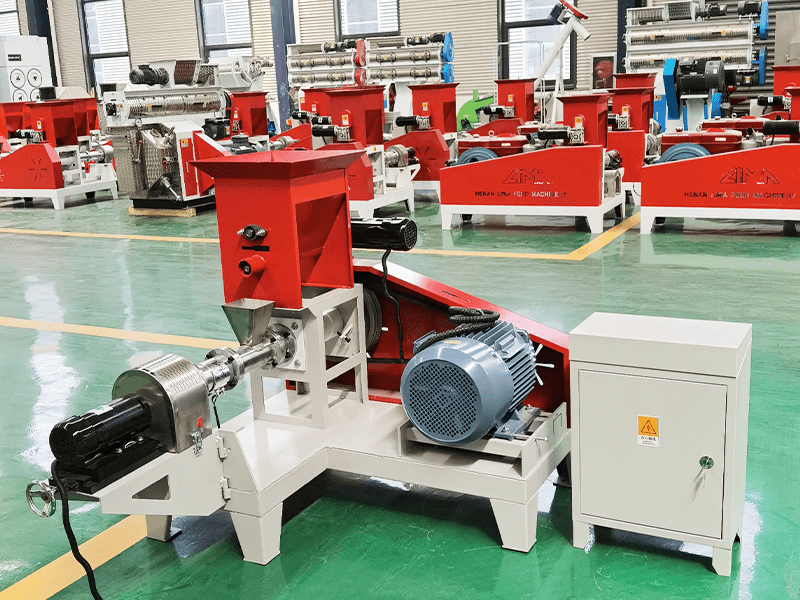

Dry Type Fish Feed Pellet Making Machine with Low Cost

Dry type fish feed pellet making machine, also known as fish feed extruder, is used to process various kinds of grains into high-grade aquatic feed pellets for fish, crab, catfish, shrimps, etc. Mostly known as low cost catfish feed machine, this dry type fish feed pelletizer has gained popularity in catfish farmers.

cost of fish feed extruder machine China supplier fish

cost of fish feed extruder machine China supplier fish feed extrusion machine. Model:VTSP120 Power:55KW+1.1KW+2.2KW three phases Power type:electricity Capacity:700~800kg/h Final pellets size:0.9-15mm Used for:making fish feed,cat food,dog food,pet food Final pellets shape:ball shape,bone shape,heart shape,footprint shape Raw materials:grains,manure,straw meal,alfalfa,rice husk,grass

Floating Fish Feed Pellet Extruder-Dry Type

Introduction of Dry Type Fish Feed Extruder Food for fishes always contains rich crude protein, but the crude protein in the food is hard to digest for the fish. After being processed by the fish feed pellet extruder, the feed can be easy to digest. Similar with wet type fish feed extruder, dry type also uses alloy steel. Dry type fish feed

Fish Feed Extruder, Floating Fish Feed Pellet Machine

Fish feed extruder is primarily used for producing high quality puffing pellets for fishes like catfish, carp, tilapia, salmon, trout, and aquarium fish, etc. A wide range of raw materials contain cereals, fish meal, soybean, other vegetable protein meals, fats and oils can be processed into pellets by Whirlston fish feed extruder

Fish Feed – Welcome! IDAH

Fish Feed. Depending on types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mill can only make fast sinking feeds; however, extruder offers more products characteristics from fast sinking, slow sinking, and floating. Models of single screw extruders for fish

China Fish Feed Extruder Manufacturers, Suppliers – Price

Fish Feed Extruder. The raw materials enter the DDC through the feeder and get cooked inside the conditioner together with steams. Input some water into the conditioner at the same time. Send Inquiry. Fish Feed Extruder Application. For floating, half-sinking, sinking fish feed.

Fish feed extrusion systems | Clextral

Clextral provides a wide range of twin-screw extrusion fish feed machines. It has played a pioneering role in the innovation and development of fish feed production since the 70’s. Clextral lines are designed to produce feed that meets the nutritional requirements of fish and other aquatic animals, with precise size and density control, whilst respecting the highest standards of water

Types Of Fish Feed Extruder – FishTankFacts.Com

Apr 03, 2020 · If you are looking for types of fish feed extruder you’ve come to the right place. We have 13 images about types of fish feed extruder including images, pictures, photos, wallpapers, and more. In these page, we also have variety of images available. Such as png, jpg, animated gifs, pic art, logo, black and white, transparent, etc.

Floating Fish Feed Extruder Machine Price For Extruding

Apr 07, 2019 · Wet type fish feed extruder machine is widely used for producing grains into high-grade aquatic feed pellets for many kinds of pet like fish, catfish, shrimps, crab, cat, dog and etc. Grain materials employed in fish feed extruder

Optimization of extruder cooking conditions for the

Dec 21, 2018 · However, extrusion is a process that involves many parameters that need to be optimized for desirable end properties. These findings guide fish feed manufacturers on the optimum conditions for single screw extruders for production of feeds with desirable properties especially for the fish

Fish Feed Extruder – Zhengzhou E.P Machinery Co., Ltd.

E.P Machinery is a reliable and professional manufacturer for producing fish feed extruders, fish feed production lines and relative auxiliary parts. We provide all the machines needed in a fish feed production line, so it’s convenient for you to purchase fish feed equipment from us.

Fish Feed Extruder Machine for Floating Fish Feed Production

Fish Feed Extruder Machine Working Process. The feed drifts down the feeder as pressure on the feed creates a uniform input. The material is squeezed with more pressure and friction. You can use electricity in the compression chamber by connecting the electric sheet to increase the heat for an easier extrusion. This chamber is suitable for

Amazing fish feed extruder price At Fabulous Offers

The fish feed extruder price are also easy to operate and maintain in their optimal operating conditions. All fish feed extruder price manufacturers and sellers on this site supply them along with their user guidelines to guide you in getting the best out of them while maintaining safety.

(PDF) DESIGN AND CONSTRUCTION OF A FISH FEED EXTRUDER

Fish feed extruder comprises of benefits it provides. The physical benefits include hopper, a barrel which houses, the screw conveyor, improved ease of handling, reduced ingredient the cutting knife, the die, a heater etc. It can be segregation, less feed wastage and increased bulk divided into wet and dry type mill.

Dry Type Fish Feed Extruder For Making Extruded Aqua Feed

Application of Dry Type Fish Feed Extruder This equipment uses corn, soybean (bean cake) animal wastes as raw materials, can be expanded to produce different particle shapes, suitable for different pet tastes such as dogs, cats, fish, birds, rabbits, shrimps, dogs, cats, donkeys, foxes, etc.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)