Fish feed extruder machines are fish feed equipment that all kinds of fish farming, aquaculture industry practitioners and feed factories want to know about. As a feed machinery and equipment specializing in the production of floating fish feed, suspended fish feed and other products, whether it can meet the required expansion degree of fish feed is a standard that can reflect the performance of feed machinery and equipment. The technological level of the wet type fish feed extruder is relatively high, which is suitable for the investment and use of large and medium-sized fish feed processing plants and aquaculture entrepreneurs in farms.

1. Wet type fish feed extruder application

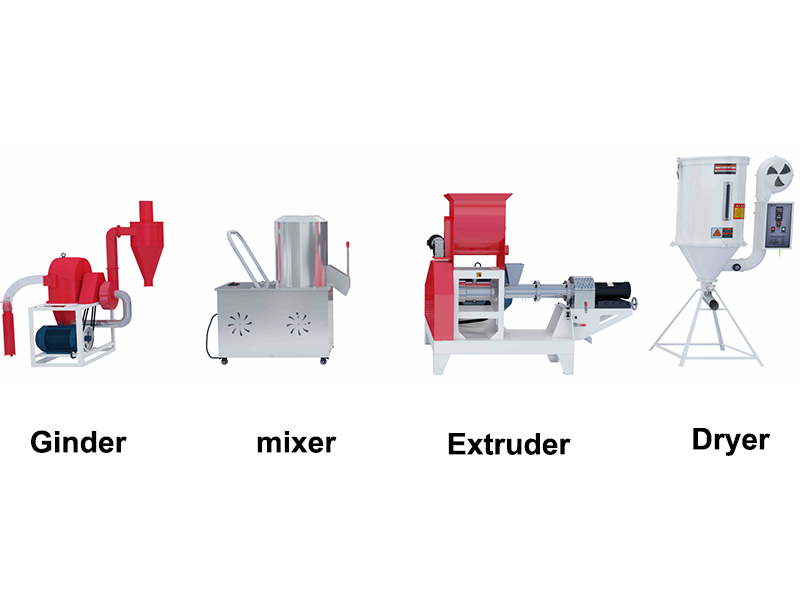

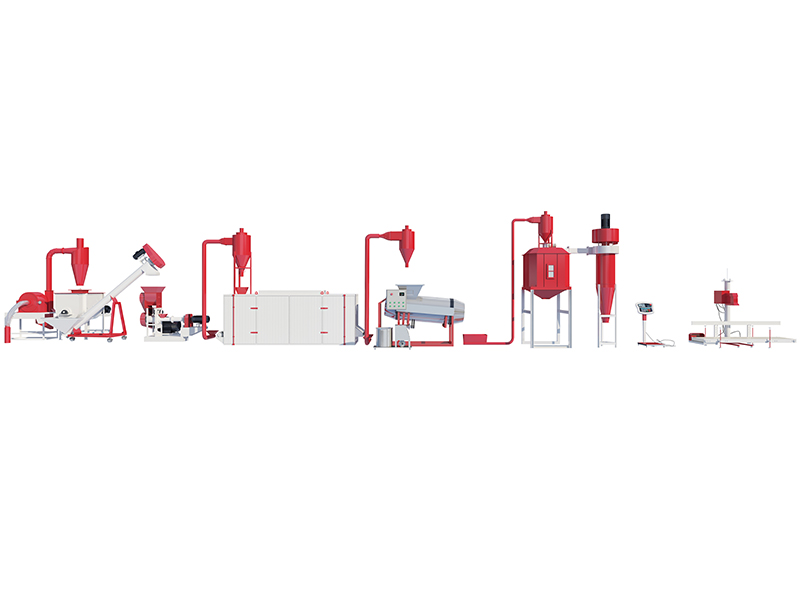

The wet-process fish feed extruder can be used to produce both floating fish feed and sinking fish feed. It is necessary to adjust the formula of fish feed for production. The output of the wet fish feed extruder is higher, and the wet fish feed extruder is equipped with a boiler, which can continuously supply hot steam to the screw during the fish feed production process, and the produced feed has higher maturity, smoother particles, and product quality. It is also better, and it is the first choice for large and medium-sized feed processing plants and farms. Wet fish feed extruders are also widely used in fish feed production lines.

2.What is wet type fish feed extruder?

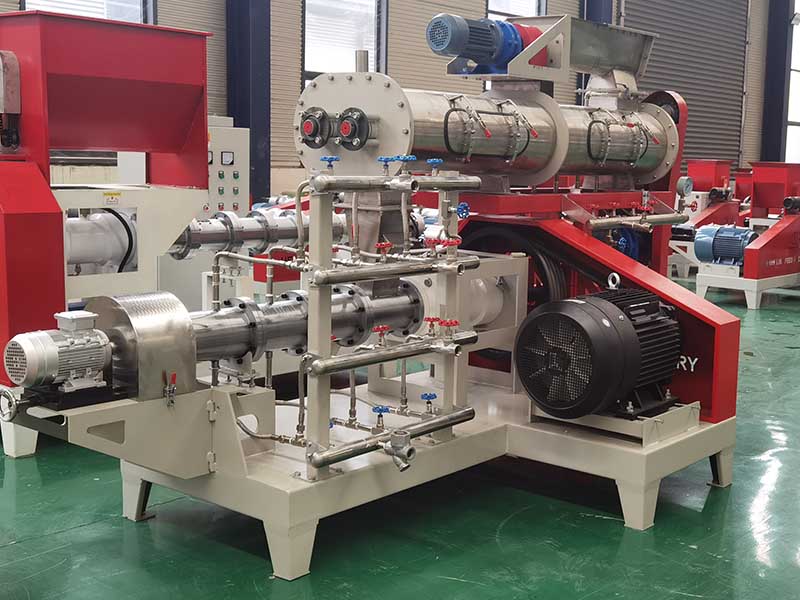

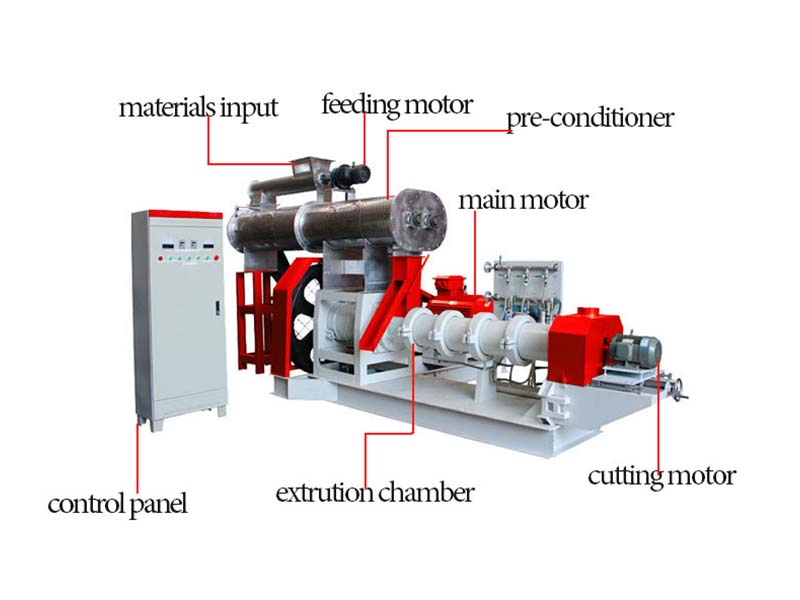

The wet type fish feed extruder machine is mainly used to produce high-quality aquatic feed such as fish, shrimp, crab, turtle, eel, loach, bullfrog, etc. It can also be used to produce pet feed such as cats and dogs. Fish feed size can be from 0.4-15mm. The fish feed extruder is divided into dry way fish feed extruder and wet way fish feed extruder. The wet way fish feed extruder is characterized by a boiler that provides steam and many small pipes for conveying steam.

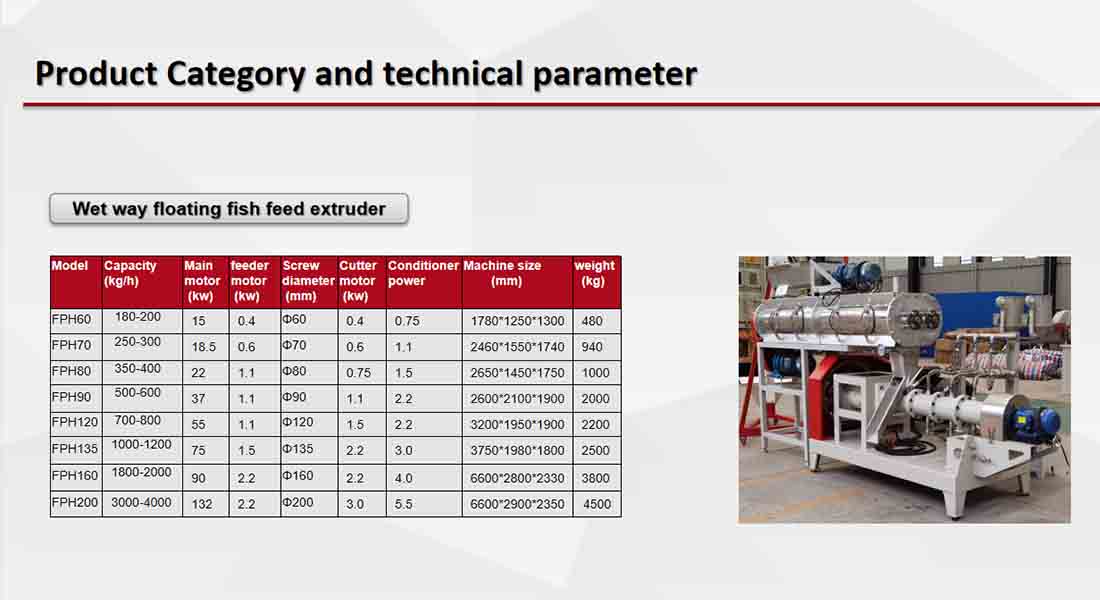

3. Wet type fish feed extruder capacity

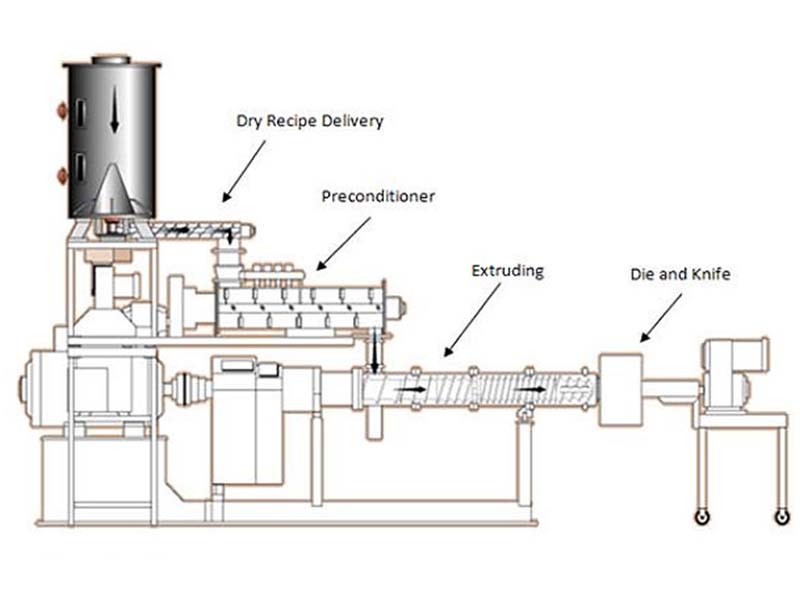

4. Wet type fish feed extruder manufacturing process

The fish feed raw material enters the extruder screw through the feeding port. During the rotating working process in a closed environment, the boiler continuously supplies steam to the screw. The raw material is fully cooked under high temperature and high pressure between the screw and the screw sleeve. The starch and fiber paste of the raw material Through the extrusion of the screw, the extruded material is pushed out of the die hole to form floating expanded particles. The size and shape of the feed pellets can be adjusted by changing molds with different apertures, and the thickness of the feed can also be controlled by adjusting the rotational speed of the rotary cutter.

5.Wet fish extruder machine features

(1) Feeding, rotary cutting and main drive are all using variable frequency speed control system, strong power, stable operation, energy saving, high aquatic efficiency, strong and durable equipment, low failure rate, convenient operation and maintenance.

(2)The screw is made of alloy material by special process, and its long service life is 3-4 times higher than similar domestic machines, and low feed production cost; segmented combined screw, a wide range of raw materials and more diverse products.

(4)The feeding system adopts spiral forced feeding, which is uniform and extensive. An automatic feeding system can be equipped

(5)Double screw has self-cleaning function, the use of equipment is more reasonable and convenient.

(6)Different screw and length ratio can meet different production processes.

(7)Processing of floating feed does not need adhesive, can be stable in water for more than 12 hours.

5. Wet type fish feed extruder advantage

1. The feed pellet products produced by the wet type fish feed pellet machine have better internal and external quality, smooth surface, high product particle uniformity and good uniformity during the extrusion process. Because the material is fully matured and mixed in the conditioner.

2. The capacity of the wet way feed pellet machine is higher than that of the dry way feed pellet machine, so usually the wet type fish feed extruder is suitable for medium and large feed pellet plants.

6. Wet type fish feed extruder maintance

(1)Other bearing parts of the puffing equipment should be regularly filled with grease.

(2)Maintenance of the extruder feeding device, the feeding device is an indispensable part of the feed dryer production line. The feeding port of the feeding device is often in contact with the material, which is easy to block and wear. The operator needs to check the feed port from time to time for blockages. When it is blocked, it needs to be cleared in time. At the same time, it is also necessary to clean up and master the wear of the feeding port in time.

(3) It is strictly forbidden to use hard objects and heavy hammers in the process of disassembly and assembly of vulnerable parts such as screws and screw sleeves of the extruding equipment, and it is strictly forbidden to place heavy objects or stand on the extruding cavity.

(4) When the feed extruding equipment is not used for a long time or the extruded materials are replaced, the materials in the extruding chamber should be cleaned to avoid agglomeration, mildew or cross-contamination between materials.