SCREW DESIGN BASICS – TAPPI

Resin Feeding Feeding of the extruder is independent of screw design. For successful operation of any single screw extruder a consistent feed stream must be supplied. The feed stream must be of uniform composition and uniform weight.

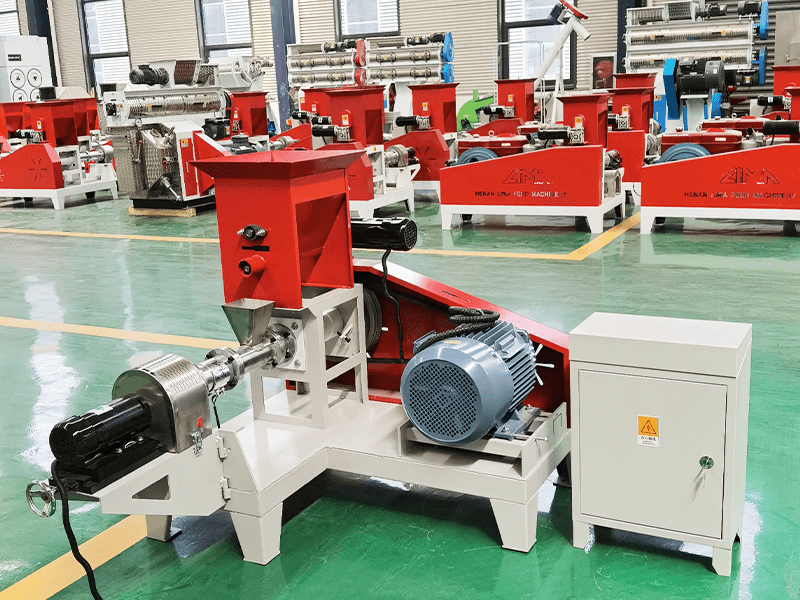

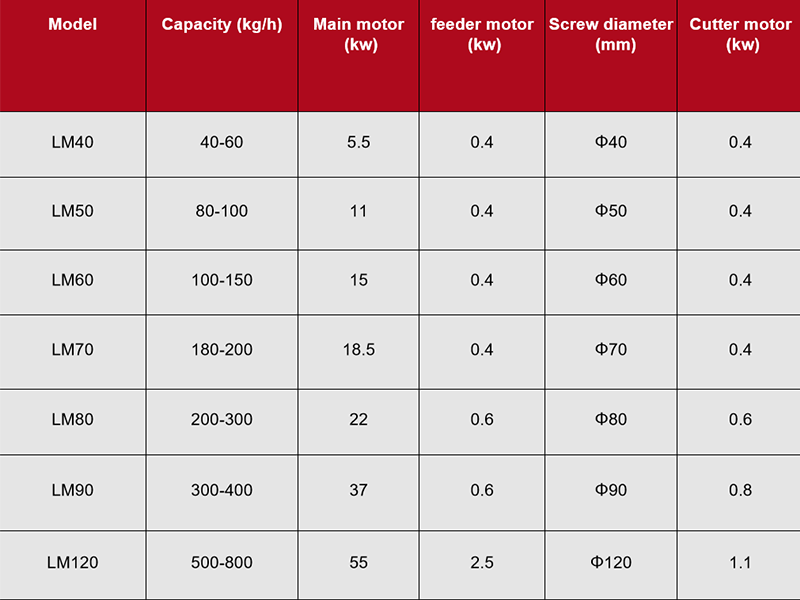

Extruder Dry – USA Pellet Mill

Extruder Dry Make your own dog, cat or fish food with our variety of high quality extruders machines, we have the solutions for your small, medium or large enterprise. Extruder Dry 11kw MKED050C. Power Type. Electric w/Panel Power. 11kW + 0.4kW + 0.4kW Capacity.

Floating Fish Feed Production Line|Automatic Pellet

Capacity of wet type fish feed extruder is higher than dry type ones, so usually the wet type extruder machine is suitable for large feed pellet factory. Pellets drying — feed pellet dryer Our mesh belt dryer is a continuous convective belt dryer.

MONOPRICE

12. Press the top button to feed filament into the printer. Allow the motor to run until it stops feeding. Repeat this process until filament starts to extrude out of the nozzle. 13. Using the included plastic scraper, clean the extruded filament from the nozzle and build platform. 14. Press the center button to deselect the Extruder entry. 15.

DEFECTS IN EXTRUSION PROCESS AND THEIR IMPACT ON

187 Int. J. Mech. Eng. & Rob. Res. 2014 S S Gadekar et al., 2014 DEFECTS IN EXTRUSION PROCESS AND THEIR IMPACT ON PRODUCT QUALITY J G Khan1, R S Dalu2 and S S Gadekar1* *Corresponding Author: S S Gadekar, sandipgadekar77@gmail.com In the 20th century, the number of manufacturers had established extrusion pipe manufacturing plants on the customer demand.

(PDF) Feed extrusion process description

Jul 01, 2010 · Feed rate, preconditioner water and steam, extruder screw speed, extruder water and steam addition, and knife speed were adjusted to achieve a wet bulk density of 330 g*L -1.

FISHING CHIMES Aquatic Feed Extrusion Technology An

(cold extruders or extruder cookers) and the method of construction (single-or twin-screw extruders). Twin screw extruders: Twin screw extruder is a better design where one screw wipes out the cavity of the other screw thus ensuring positive displacement of feed materials through the

dry type fish feed extruder diesel engine fish feed

Dry type fish feed extruder is adopted to process various kinds of grains into high-grade aquatic feed pellets for fish, catfish, shrimps, crab, etc. Final pellets produced by fish feed extruder have a unique shape, good taste and balanced nutrition. it can be driven by electric motor and diesel engine motor,when driven by diesel engine motor,the diesel engine is electric start which can save

Floating Fish Feed Extruder-Dry Type – feed-pellet-mill.com

The fish feed pellet extruder can be divided into two types: dry type fish feed extruder and wet type extruder. The Differences between Dry Type Extruder and Wet Type Pellet Mill 1. Dry type fish feed extruder does not need the steam boiler, so the dry type fish feed pellet machine is cheaper and easier to use and operate. 2.

Commercial Aquaculture Feed Production (Floating Feeds)

Extruder Raw feed ingredients Extruded products Conditioner Feed Bin Steam Water Steam Water Dryer / Cooler. Feed Conditioning Extruder Rotating Cutter Pneumatic Transfer Especially fish bones (from fish meal) Competing Effects during Extrusion Ingredients + processing conditions + product quality. Extrusion Challenges Fiber content

An Introduction to Single Screw Extrusion

Extruders may be categorized by three figures, for instance, 16024. granulated to form the feed for another process, such as extrusion or injection molding. … However, it must be remembered that it would be more appropriate to predry the polymer, because heating certain plastics in

Fish Feed Machines and Floating Feed Production Line

Single screw fish feed processing line can be divided into 2 types: Small Dry Type Plant and Large Wet Type Plant, in accordance with what extruder you choose. WET TYPE: Super automation control and high production efficiency, it is the best choice for medium and big sized feed mills and breeding farms. This processing line can produce various kinds of pellets for different varieties of fishes

Pet Food | Wenger

Aquatic Feed Floating, sinking, slow-sinking and specialty products; Food Breakfast cereals, pastas, snacks, breadings, textured vegetable proteins; Pet Food Dry, semi-moist, high meat, co-extruded, multi-colored, and novelty shapes; Industrial Products and ideas for boundless purposes

FISHING CHIMES Aquatic Feed Extrusion Technology An Update

(cold extruders or extruder cookers) and the method of construction (single-or twin-screw extruders). Twin screw extruders: Twin screw extruder is a better design where one screw wipes out the cavity of the other screw thus ensuring positive displacement of feed materials through the

Feed extrusion process description – SciELO

Increasing the dry feed throughput will in effect reduce the open area in the final die per unit of throughput. This reduction in open area results in greater expansion. As the feed rate is increased beyond a certain point the density begins to increase due to the loss of retention time in the preconditioner and extruder

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)