粉碎技术_图文_百度文库

Oats 燕麦 1 Barley 大麦 2 Wheat 小麦 3 Corn 玉米 4 Example:举例 加工燕麦产量1500kg/h,加工玉米产量6000kg/h If the throughput for oats is 1500 kg/h,it will rise to 6000 kg/h for corn.(factor 4) 5/29/2012 CPF Feedmill KnowledgeBase 73 影响粉碎加工的因素

Wood Pellet Machine and Feed Pellet Machine

Scientifically formulated Forage Grass Pellet Feed Processing Production Line project 1. Project name: 5000 tons/year forage grass pellet feed processing production line project 2. Project construction site: Inner Mongolia 3. Necessity and feasibility of project

(PDF) Development of a Cassava Pelleting Machine |

E-mail: bobboiumar@yahoo.co.uk Phone: 08023825894Prof. A. A. Olufayo – Editor, Soil and Water EngineeringAgricultural Engineering Department, Federal University of

Other – Vacuum Forming Machine – The Trout Underground

ENERGY EFFICIENT MACHINE WELL SUITED FOR PROTOTYPE OR PRODUCTION WORK FOR FURTHER INFORMATION CALL US 678-860-1741 THIS IS A BUILT TO ORDER MACHINE. BUILD TIME IS ABOUT 3-4 WE Used Sibe Automation SBA 1218 12″ x 18″ vacuum forming machine

MZLH-420 Sawdust Pellet Mill For Sale | Pellet Plant | RICHI

MZLH-420 Sawdust Pellet Mill RICHI MZLH-420 sawdust pellet machine can production wood pellet, it is widely used for recycling usage of wastes and tailings in biomass fuel plant,power plant,wood processing plant,furniture factory, fertilizer plant,chemical

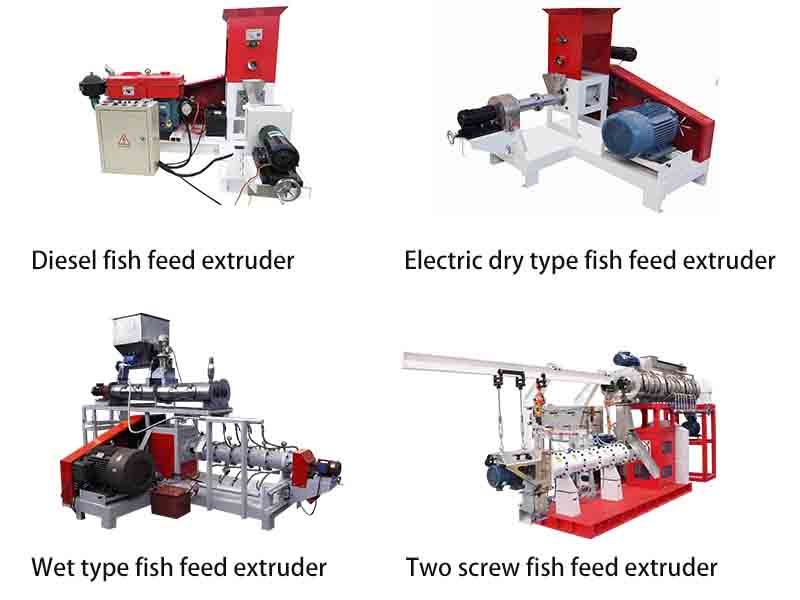

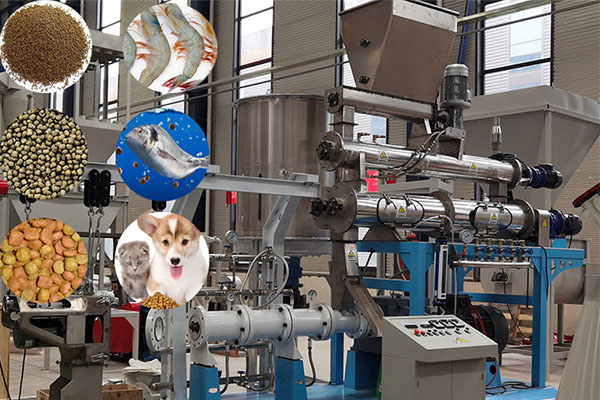

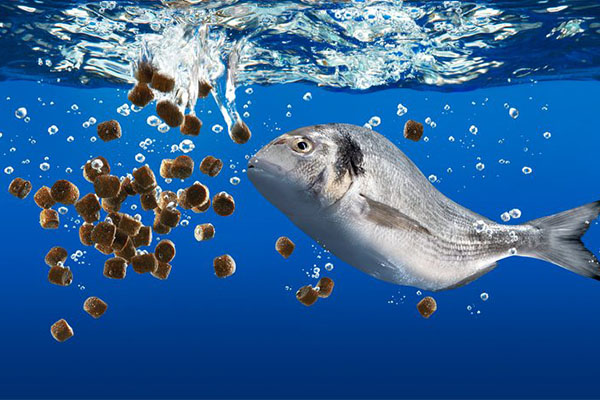

Fish Feed Processing Line – Shrimp Feed Making Machine

Fish Feed Processing Line Leading Manufacturer of shrimp feed making machine, fish feed pellet making machine, small floating fish feed making machine, small fish feed extruder, single screw floating fish feed extruder and sinking fish feed making machine from Pune.

Biomass for Electricity Generation | WBDG – Whole Building

Some of these systems are available in the United States, with outputs from about 2 kilowatts (kW), and approximately 20,000 British thermal units (Btu) per hour of heat, to several megawatts (MW). In addition, small-scale (100 to 1,500 kW) steam engine/gen-sets and steam turbines (100 to 5,000 kW) that are fueled by solid biomass are currently available in Europe.

Design of experiments optimisation study on the fat

The fat coating machine has a maximum loading capacity of about 60 kg extrudates per batch and the maximum rotational speed is 16 rpm. The electric motor is in turn regulated by a 3-phase voltage converter with the maximum voltage of 400 volts.

China Full Automatic Floating Fish Feed Pellet

The animal feed pellet making machine is one of the key machines in feed pellet production line. It’s die mold is made of stainless steel or alloy steel for your choice. It has the characteristics of low cost, reasonable structure, compact layout, reliable performance and easy maintenance.

How much KWH does your house use per day – Green Energy

Washing machine uses 0.2kwh per wash. our overall use was around 9-10kwh per day, has now dropped to 7-9kwh after switching off a lot of standby load.. 2A + 2C family, double story 1950’s solid brick home.

Infloor Radiant Design Guide | Healthy Heating

Electrical hp: a measure of time rate of mechanical energy output; usually applied to electric motors as the maximum output; 1 electrical hp is equal to 0.746 kilowatts or 2,545 Btu per hour. Shaft hp: a measure of the actual mechanical energy per unit time delivered to a turning shaft; 1 shaft Hp is equal to 1 electrical Hp or 550 foot pounds per second.

30 Tons/day Straw Pellet Production Line Project

2T/H Wood Pellet Production Line In 1200-1500KG/H Fish Feed Pellet Prod Trinidad and Tobago 4000-5000KG/H A Zimbabwe 3-5T/H Chicken Feed Pellet USA 10-12T/H Forage Grass Pellet Pr Uzbekistan 3-5T/H Animal Feed Pelle

Ring Die Wood Pellet Machine for Industrial Scale Pellet

It can be used to produce pellets within the range of 2.5mm to 12mm as the clients’ requirements. The universally approved standard for a ring die is 8mm or 6mm. The rollers are sitting on the eccentric shaft. With the help of a bearing, you will be able to assemble the rollers.

Sale Poultry Feed Pellet Machine For Sale

This MKLH ring die pellet machine capacity ranges are from 500kg to 1500kg per hour. According to the characteristics of biomass fuel pelletizing, it is mainly designed for pressing combustible materials such as saw dust and grass into pellets.

(PDF) Design of experiments optimisation study on the fat

The fat coating machine has a maximum loading capacity of about 60 kg extrudates per batch and the maximum rotational speed is 16 rpm.