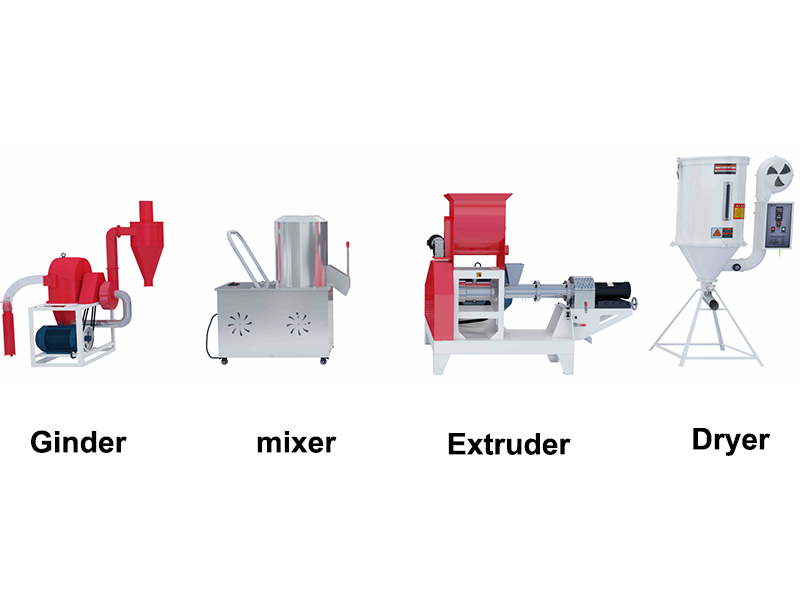

spare parts installation of floating fish feed pellet machine

Contact:Miss SusanEmail:susan@goldenmachinery.cnEmail:goldenmachinerysue@163.comSkype:annieshuang1129Wechat:goldenmachinerysueWhatapp:86-15838007835TEL:0086-

Parts of Extruder – PTFE Machinery

9. Extruder tempering system – Usually it is a closed circuit type with electrical heating. Both single – and twin – screw extruders may use hot oil circulation systems for temperature regulation. The sump temperature is set to 204 degrees, and the extruder barrel is heated or cooled depending upon internal heat generation.

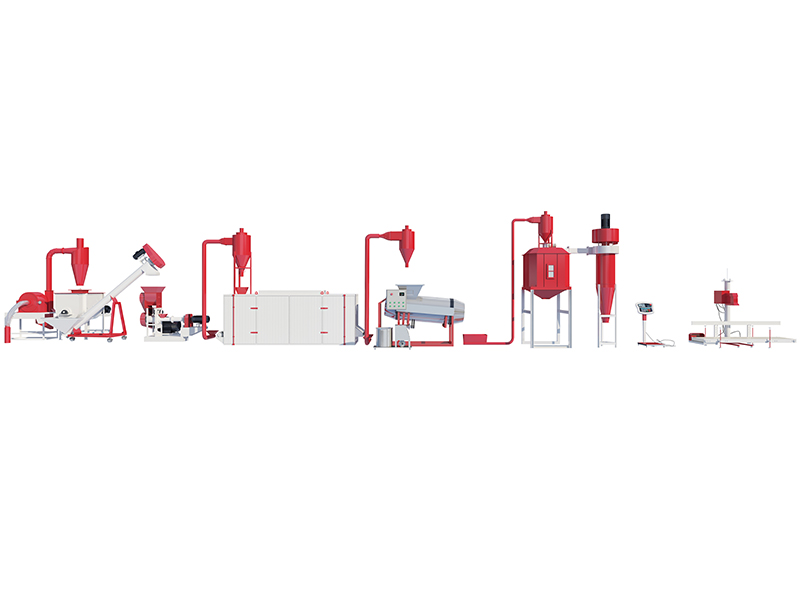

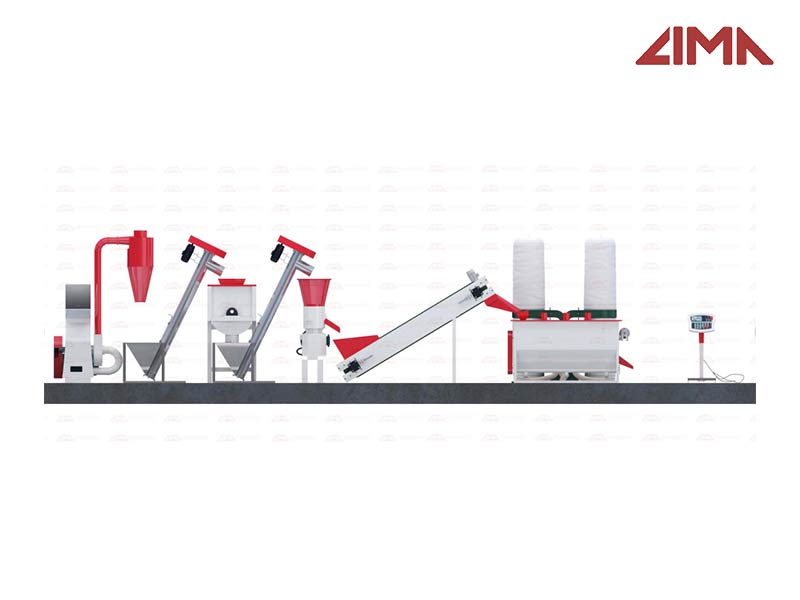

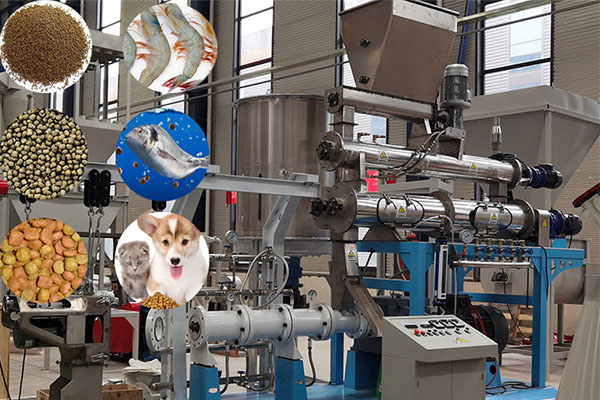

Shrimp Dog Food Line Animal Floating Fish Feed Pellet

Shrimp Chicken Dog Food Animal Floating Fish Feed Pellet Production Line,Pet Food Extruder,Poultry Feed Processing Equipment . 1). The fish feed pellets can float on water for over 20 hours.And sinking and floating aqua-feed pellets both can be made just by adjusting the feed formulation. 2). Pellet diameter is 0.9mm-15mm by changing the mold.

Feeders for Extruders- Which Feeder Works Best for Your Products?

Sep 18, 2014 · This type of feed system represents our most basic configuration and accounts for a high percentage of the equipment that goes out the door. Force Feed or Side Feeders- Some products that we extrude present a challenge in keeping products feeding to the extruder and require direct feeding into the inlet chamber.

(PDF) Design and development of livestock feed pelleting machine

Khater et al. (2014) showed that physical and mechanical properties of fish feed pellets such as bulk density, durability, moisture content and crushing load were varied from 267.11 to 711.35 Kg/c

How to Feed Catfish – Fish Feed Extruder

Under the conditions of pond culture, adult catfish feed can refer to the following formula: 25% fish meal, 18% peanut powder, 5% yeast powder, 1.1% fish oil, 10.4% corn powder, 2% compound amino acid, 2.5% premix.

Extrusion Cooking Technology for Foods: A Review

Extruder feedrate depends on the types of screw element, screw speed, type of feeding element and feed moisture. The federate has an influence on residence time, torque requirement, barrel pressure and dough temperature. 2.2 Feed Ingredient Variables Feed composition, moisture content and particle

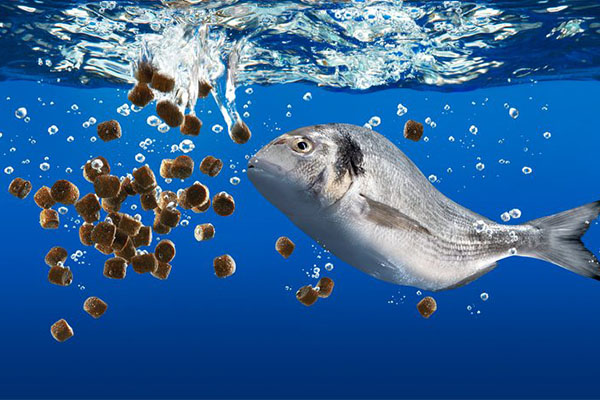

Commercial fish feed – Wikipedia

Manufactured feeds are an important part of modern commercial aquaculture, providing the balanced nutrition needed by farmed fish.The feeds, in the form of granules or pellets, provide the nutrition in a stable and concentrated form, enabling the fish to feed efficiently and grow to their full potential.

Pet Food Extruder Machine – Loyal Industrial Manufacturer

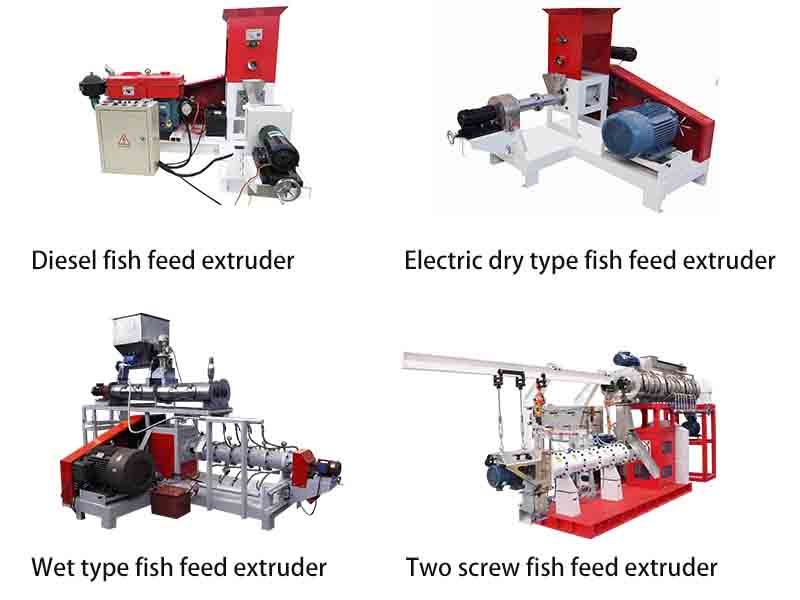

As Pet Food Extruder Machine manufacturers had designed High Quality Twin Screw pet Extruders used for pet food and fish feed production, developed and tested. The major components of the machine included the feeder hopper, the conditioning chamber (can be choose), the barrel that was a screw member housing and the screw with the die and die holder fitted at the extreme end of the barrel.Twin

The preparation of floating & sinking fish feeds by extrusion

Jan 05, 2017 · A fish feed manufacturer can take advantage of this by operating his extruder under conditions where he has minimal dextrin formation, if desired, or under conditions where varying levels of the starch is dextrinized. He can increase the dextrin level by operating at higher temperatures and lower moisture.

High Quality Alloy Steel Fish Feed Machine Spare Parts

Fish feed extruder comprises of hopper, a barrel which houses, the screw conveyor, the cutting knife, the die, a heater etc. Screw Shaft Screw shaft is the main component of extruder.

home-used small type floating fish feed extruder

Floating Fish Feed Extruder. Floating Fish Feed ExtruderIntroduction: 1. Composed of feeding system, extruding system, cutting system, controlling system. 2. Adopt Auto-temperature Controlling System which making it more precise and viewable to control the temperature. 3. Combined main shaft can apply to a variety of materials 4.

Extruded Floating & Sinking Fish Feed Processing and Application

Extruded Floating & Sinking Fish Feed Pellets Production Process. On the basis of density variation and puffing degree, extruded fish feed can be segmented into floating fish feed and sinking fish feed. Currently, the floating feed is the most widely used extruded feed in fish farming, and it has relatively mature technology.

FEED AND BIOFUEL ADVANCED FEED PRODUCTION TECHNOLOGY

• Extruder capacity Back pressure valve (FLEXTEX™) and Expansion Control System (ECS™) combining two unique process technologies for full feed controllability. THE PHYSICAL QUALITY OF FISH FEED PRODUCTS IS DEFINED BY: • Density • Shape and size • Uniformity • Durability • Water stability • Fast sinking / slow sinking / floating

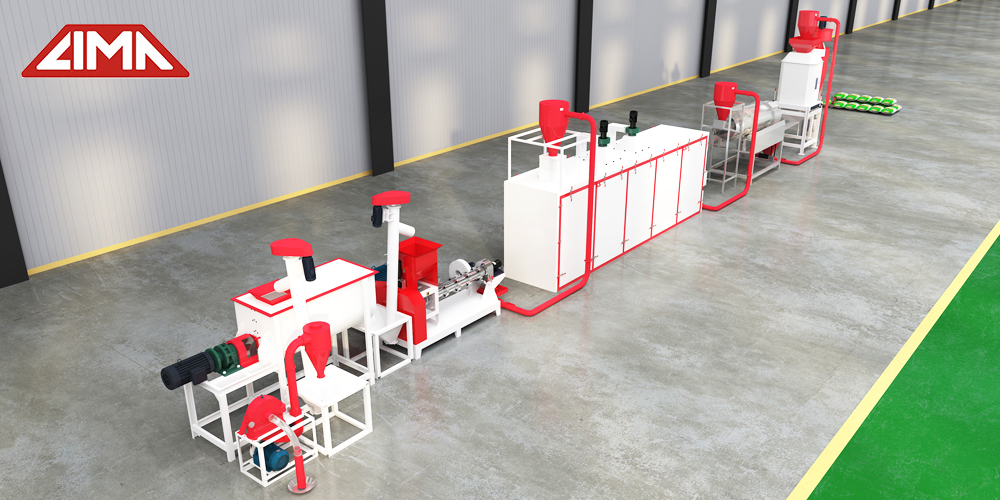

Feed extruder production line / fish feed production line

Feed extruder production line is a feed pelle production line. It mainly processes crushed grains, straw, husk, and fish meal, meat meal, bone meal into feed pellet to feed aquatic animals and pets. The whole feed pellet production line includes two types, dry process and wet process. Both lines output feed pellets with high automation.