How Many Types of Feed Extruders Are There?

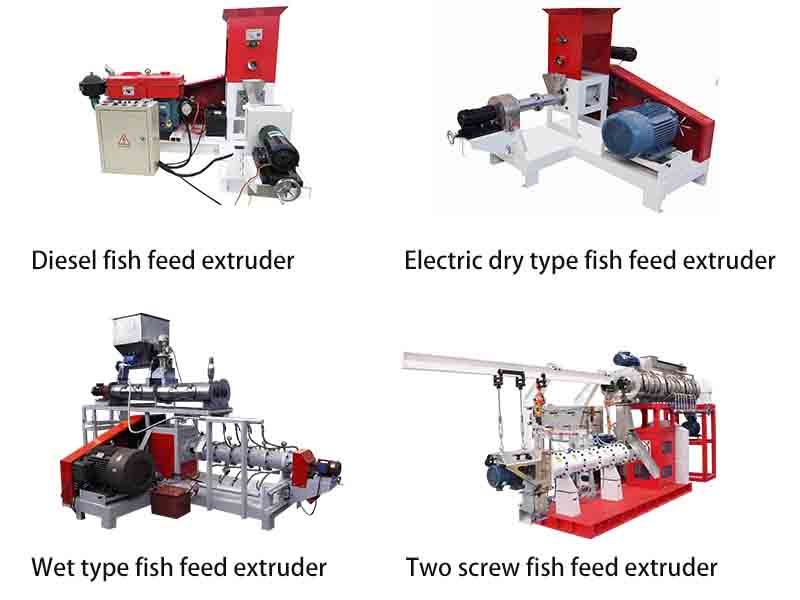

Usually, feed extruder have two types, single screw extruder and and two screw extruder. According to the industry where the extruder is applied, we can also divide it into two types, one is a types of extruders used in food industry, and the other is animal/Aquatic feed extruder.

Common feed pellet extruder machine are: floating fish feed extruder machine, poultry feed pellet machine

1.Floating fish feed extruder machine

Fish feed pellet machine has motor type, semi-diesel type, diesel engine model of three models, fish feed pellet and dry method and wet method of granulation machine, fish feed pellet machine and single screw and double screw models.A variety of different feed pellet machines, in appearance and production mode is different from by classification. The main characteristics of the fish feed pellet machine are as follows.

1).Simple structure, wide adaptability, small land area and low noise.

2).Powder feed and grass powder can be used for granulation without the need or a little liquid addition, so the moisture content of granule feed is basically the moisture content of the material before granulation, which is more conducive to storage.

3).Granulmachines can obtain higher economic benefits than mixed powder feed.

4).The production of feed particles with high hardness, smooth surface, internal ripening, can improve the digestion and absorption of nutrients.

5).Granule formation process can make the pancreatic enzyme resistance factor in grains and beans undergo degeneration, reduce the adverse effects on digestion, kill various parasitic eggs and other pathogenic microorganisms, and reduce various biological worms and digestive system diseases.

2. Poultry feed pellet machine

Poultry feed pellet machine can be divided into flat mold pellet machine, ring mold pellet machine.

Using template, pressure roller using high quality alloy steel by special treatment, spindle and flat mold under the action of friction, drive pressure roller rotation, pressure roller and template produce high temperature starch ripening, protein degeneration solidification, under pressure roller extrusion from the hole in the mold, particles through plate, by adjusting the knife Angle can control particle length, da machinery is mainly suitable for medium and small-scale breeding professional processing production of livestock and poultry and aquatic pellet feed, can reduce the cost of breeding. Can be used for raising rabbits, chickens, ducks, geese, fish, pigs, aquatic products, etc.

Back to List