(PDF) Fabrication and Evaluation of Screw-like Fish Pelletizer

A pelletizing machine for the production of fish feed was designed and fabricated. It consists of a hopper, barrel which houses the screw conveyor (auger), the cutting knife and the die orifice.

ABC Africa Group – Agricultural Equipment you can rely on.

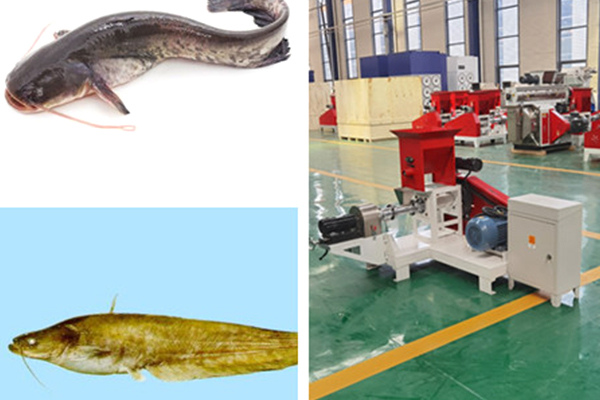

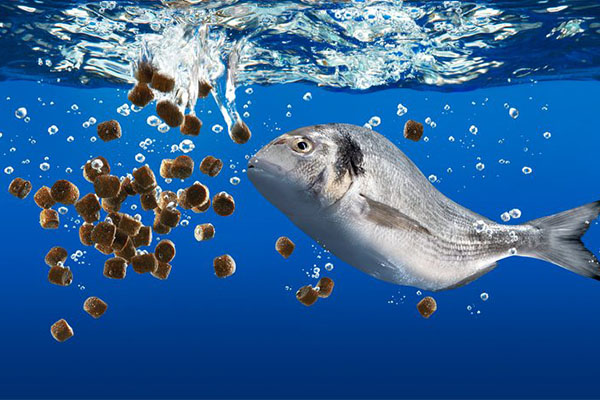

Fish feed is categorized as either floating or sinking pellets. Sinking pellets for bottom feeders (such as catfish) can be processed by means of a pellet machine while floating pellets (for top feeding fish such as tilapia) require to be extruded in an InstaPro extruder.

Cattle Feed Pellet Mill-How to Make Cattle Feed

In this process, fatty ingredients are added to the materials in order to raise the nutritional value of the feed. The feed obtained from the mixer is blended with molasses. ★ Assorted animal feed that is crushed into fine particles is further formed into pellets by a cattle feed pellet mill.

Feed Mill Design – SA Trade Hub

Pelleting System Horizontal Cooler 18-21 cubic meters per minute of air per metric ton of capacity. High maintenance. Conterflow Cooler 12-16 cubic meters per minute

Manure Pellet Machine | how to make organic manure |

This machine is designed dedicatedly for organic fertilizer granules manufacturing. It mainly turns the powdery manure compost into granules by stirring teeth. And the moisture content of raw materials for processing should be about 20% and 35%.

Profitable Fish Farming – Practical advice for profitable

I’m a catfish farmer myself, hence, my floating pellets are properly prepared with a 58%(CP)crude protein good and well balance fish feed formulation. Available sizes are 0.2mm to 10mm suitable for juveniles to maturity, we supply Nationwide to your farm or doorstep at an affordable price of NGN2,500 per 15kg.

Pellet Mill for sale | eBay

Techtongda 8mm Chicken Feed Pellet Mill Machine for Large Animals 220v 3kw $907.25 New TECHTONGDA 5mm Chicken Feed Pellet Mill Machine Green 220v 3000w $1,217.30 New 1 PC Chicken Feed Pellet Mill Machine 220v for Duck Pig 2mm Device $949

Chapter 18. Feed Milling Processes

The transformation of a soft, often dusty feed into a hard pellet is accomplished by compression, extrusion, and adhesion. The general process involves passing a feed mixture through a conditioning chamber where 4 to 6 percent water (usually as steam) may be added.

cassava animal feed

Pellets are produced by feeding dried cassava chips into the pelleting machine, followed by screening and bagging for export. Powdered chips which fall down during pelleting are re-pressed into pellets and the process repeated. There is usually about 2-3% loss of weight during the process.

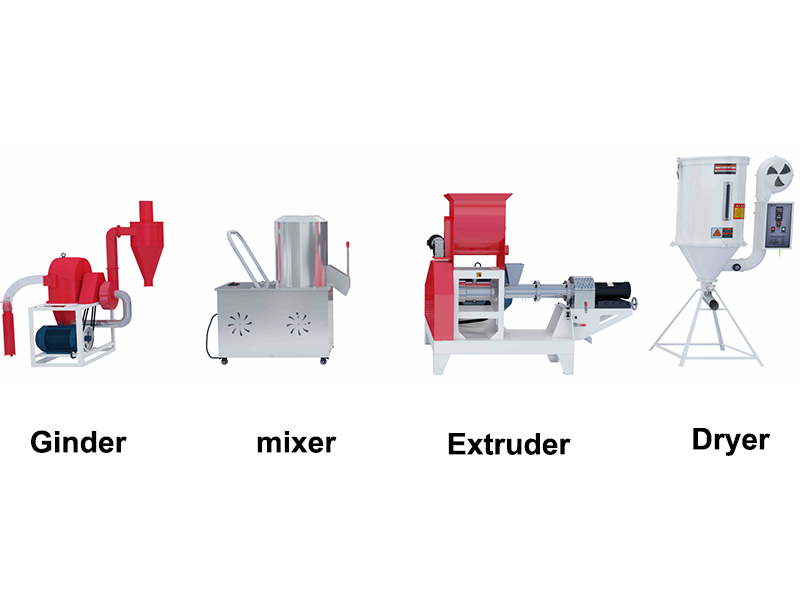

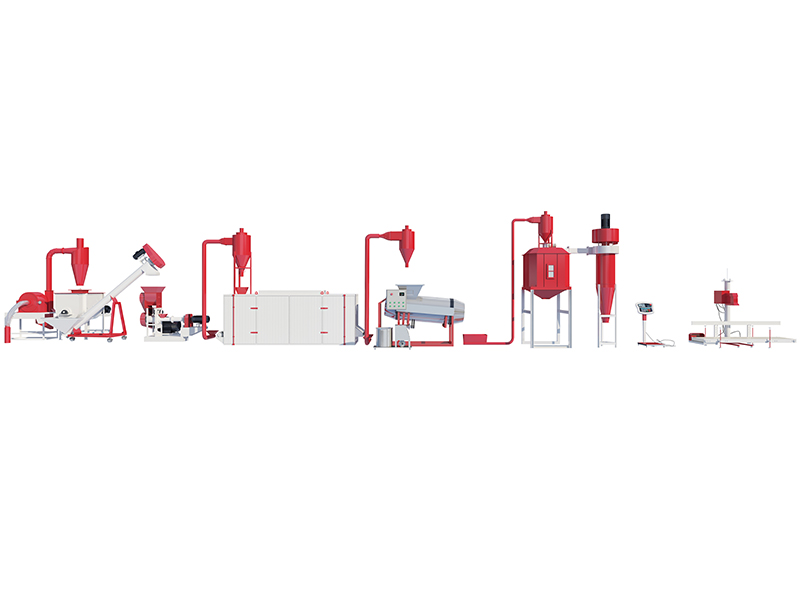

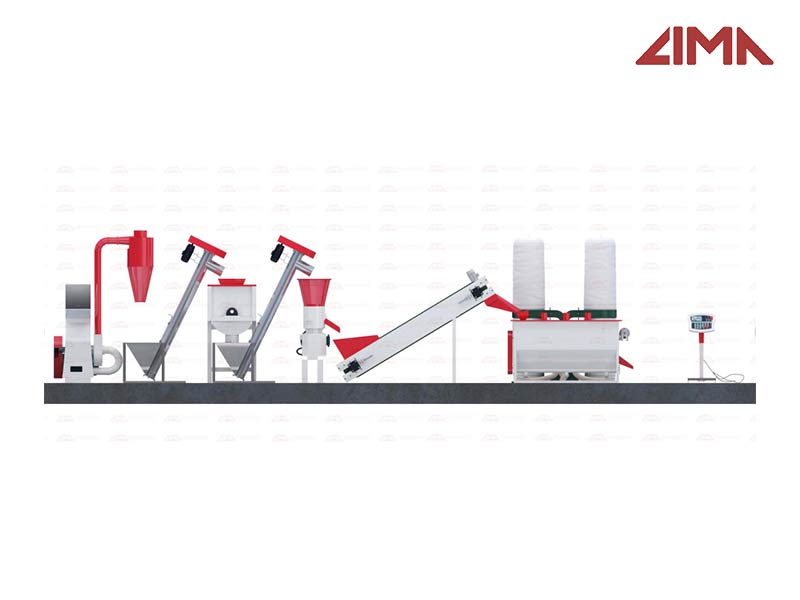

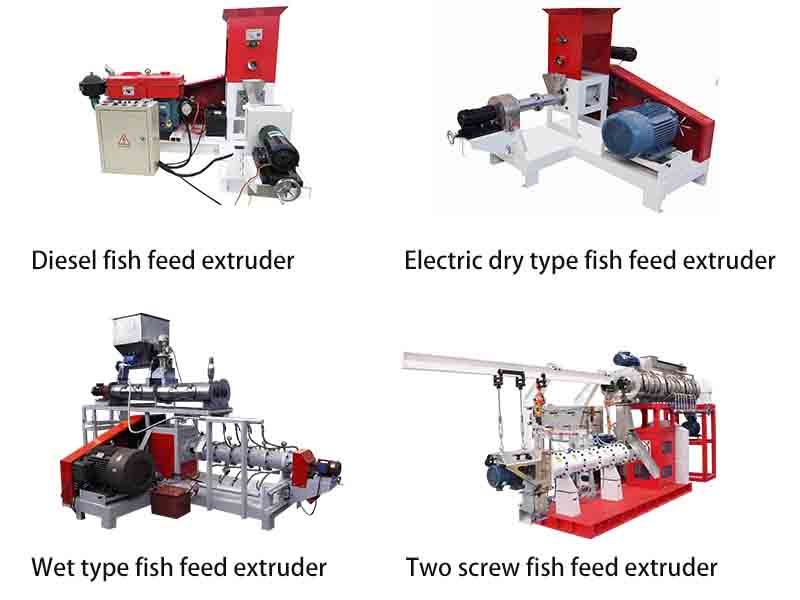

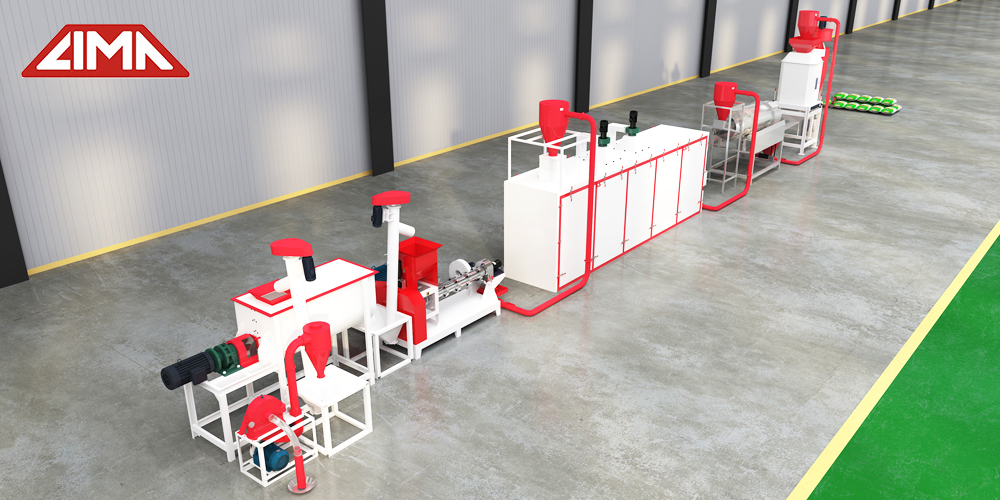

Qualified Fish Feed Extruders and Feed Production Line by

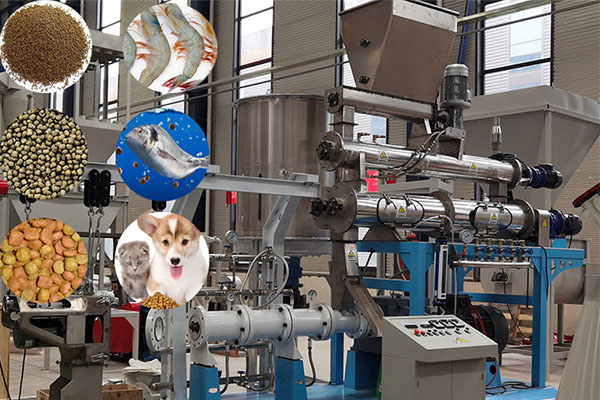

The popular machines for pellet extrusion are wet type fish feed extruders and dry type fish feed extruders. 2.Pelleting Pelleting is the process to compress small particles into larger solid with a given shape and texture, which involves the combination of moisture, heat and pressure.

HOME – Feed Pellet Mill Manufacturer/Expert In Feed

Floating Fish Feed Extruder-Dry Type It is used to make fish feed pellets with dia 0.9-15mm. Really cost-effective for aquatic farms to make their own fish food. Make floating feed pellets for all kinds of fish, shrimp and other aquatics animals.

Pelleting Machine, Pelleting Machine Manufacturers &

Get pelleting machine at best price with product specifications. Listed pelleting machine manufacturers, suppliers, dealers & exporters are offering best deals for pelleting machine at your nearby location. Centrifuge, capsule filling machine, tablet press machine

Animal Feed Pellet Machines – Nukor Turn-key Small to

The best option for Animal Feed Pellet Machines in Agriculture for Africa. Make Your Own Animal Feed from Turn-key Small to Industrial Scale Production Lines for Cows, Pigs, Sheep, Chicken and Fish. We offer a full range of tested and proven feed processing systems that make the manufacturing of animal feed both labour-saving and cost-effective.

-Superior Quality Cattle Feed Pellet Plant/Livestock Feed

The main purpose of this operation is to convert mash feed into pellet form by mixing with steam. The mash feed is fed from the storage bin to the feeder, and thereafter to the conditioner, where dry saturated steam is mixed with the feed, and then fed to the at a

Feed Pellet Making Machine – Pellet Mills Latest Price,

Find here Feed Pellet Making Machine, Pellet Mills manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Feed Pellet Making Machine, Pellet Mills, Feed Pellet Machine across India.