How Does a Fish Feed Extruder Work?

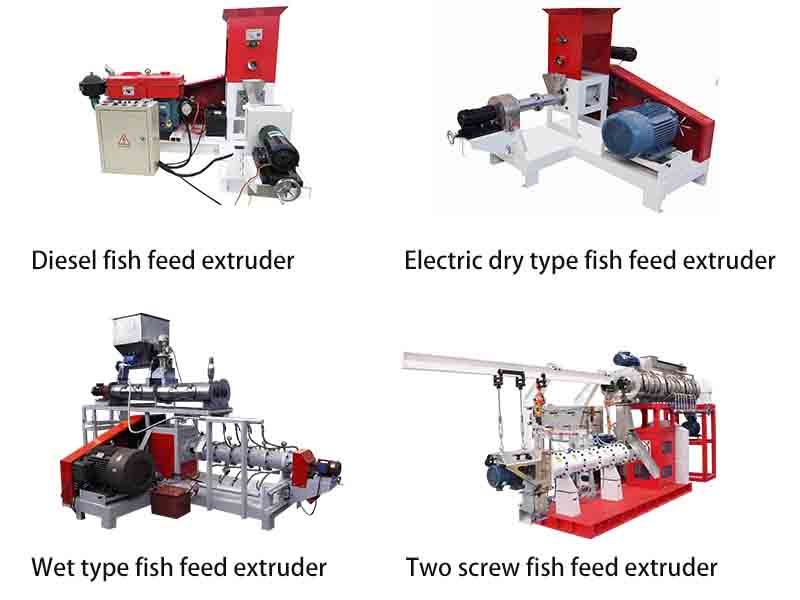

Floating fish feed extruder work also called floating fish feed making machine or fish feed pelleting machine, which is the main equipment of the floating fish feed process and fish feed production line. Now, let us discuss how does a fish feed extruder work?

1.Fish feed extruder machine preparation before work

Before Fish feed extruder machinery working. the raw materials, temperature, water and other process parameters can be adjusted , so that the Floating fish feed has the characteristics of novel shape, unique taste, rich nutrition, delicate organization, suitable for the taste of different pets. The raw corn flour, rice flour, bean flour, meat flour, grain flour, additives and other ingredients add a certain proportion of water fully mix evenly.

2.The fish feed pellet machine process

Using motor for power spiral delivery, will mix the raw material to the extruder feed bucket, ensure convenient and fast feeding, in high temperature and high pressure environment, screw extrusion, through the adjustment process production department of different feed, specific particle size and shape can be replaced mold, temperature between 0-200 degrees by control cabinet, internal for stainless steel double mesh bag, reduce the feed particle moisture, promote ripening rate, increase the shelf life.

3.Fish feed pellet mechanism grain process

Fish feed machinery has advanced double screw extrusion technology, screw using a special arrangement, to increase the flexibility of the product. Extruded warehouse through special installation to ensure product consistency and nutritional equilibrium. Fine drum spraying seasoning after the product surface without harsh edges and corners of the finished feed, early raw materials in the expansion machine fully knead and mixed, starch denaturation, protein ripening, add a variety of nutritional functions. Fish feed machinery to shorten the batching cycle, reduce the weighing process, fast speed, high accuracy, but due to the difference in the form of the measurement device, weighing range, so the use of batching device, correspondingly increased investment costs, it is difficult to achieve automatic control, is not conducive to maintenance, debugging and management.

Back to List