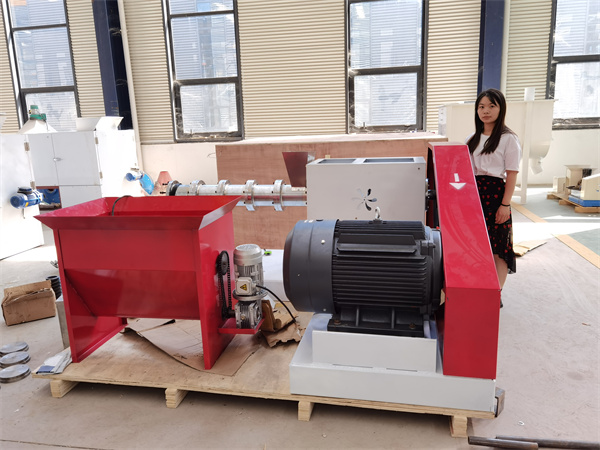

Floating Fish Feed Extruder Machine By Wet/Dry Way

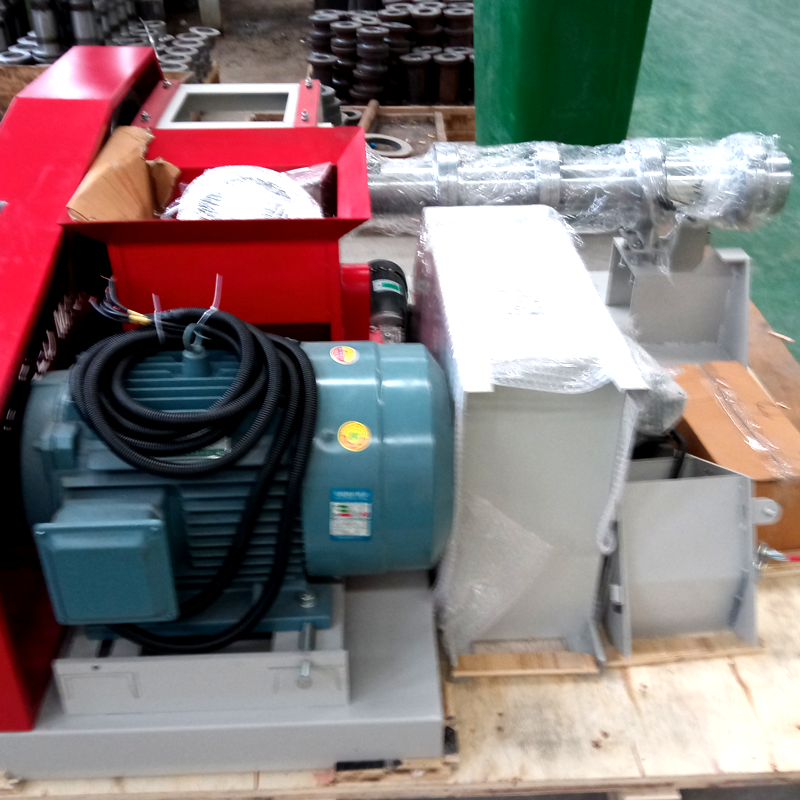

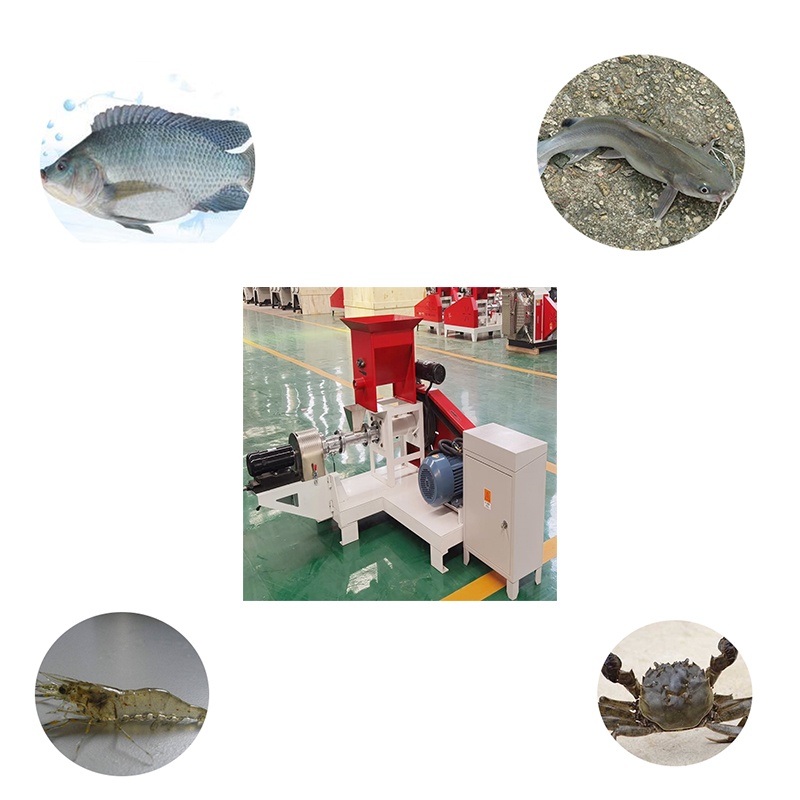

According to the moisture content of the raw materials, fish feed extruders can be divided into dry and wet fish feed extruder machines, which produce dry and wet fish feed pellets. Customers can choose based on their needs.

LIMA fish feed machine manufacturer

Henan Lima Machinery Co., Ltd is a leading manufacturer of pellet feed machines in China. Its floating fish feed extruder machine has been sold worldwide, including in Nigeria, Malawi, Ecuador, Pakistan, and Thailand. Clients can buy small fish feed machines, poultry food machines, and large fish feed and feed production lines to satisfy their needs.

The dry fish feed extruder machine

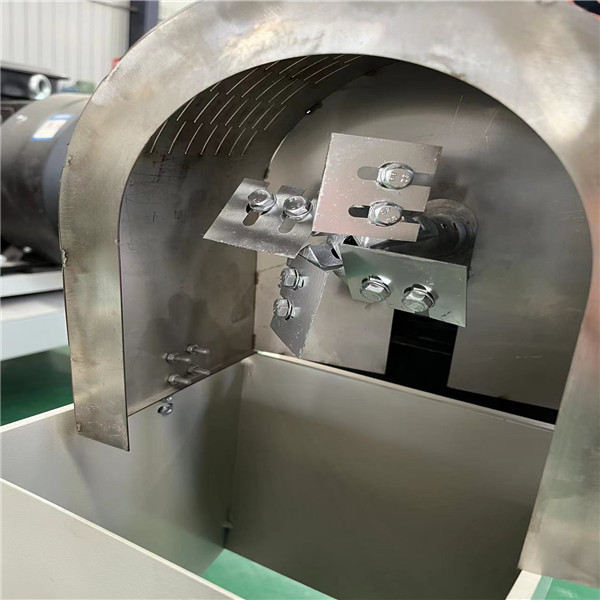

This floating fish feed extruder uses a screw extruder to extrude the raw material through the opening of the die, heating the object by friction. As the pellets leave the machine, their pressure, temperature and moisture content drop dramatically. The ingredients are then expanded to form porous particles. During operation, the moisture content varies between 15% and 20%. Single screw extruder is another name for dry fish feed pellet machine. The single-screw extruder works relatively smoothly and has strong shearing force, but the discharge port is easily blocked. Mainly used for processing raw materials, poultry and breeding feed. Manual disassembly and cleaning is required each time it is used. But when the raw material is extruded, the distribution of heat is not uniform. The curing uniformity is poor, the moisture content is low, and the scope of application is limited.

The wet fish feed extruder machine

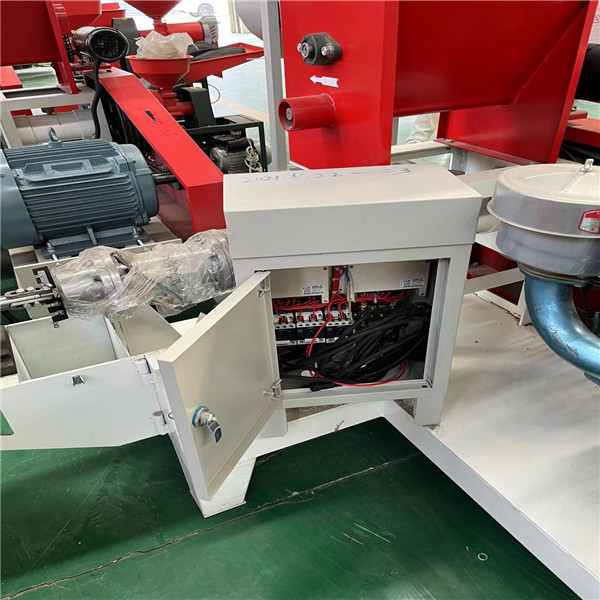

The working principle of the wet type is similar to that of the dry type. But the former requires adding water or steam to the machine to increase the moisture to 20%, or more than 30% in the process. The purpose of the steam regulator: to increase the temperature of the material, soften and solidify the material, and replenish the moisture of the raw material.

The wet type fish feed pellet machine is equipped with a preparation device for maturing feed raw materials, and is usually used for mass production of feed lines. It can produce neat, uniform and beautiful ultra-small particle size particles, with good self-cleaning effect, no need to disassemble, maturity Good, high water content, wide application range, can produce high oil, high moisture materials, mainly used in aquafeed, pet food and animal feed.