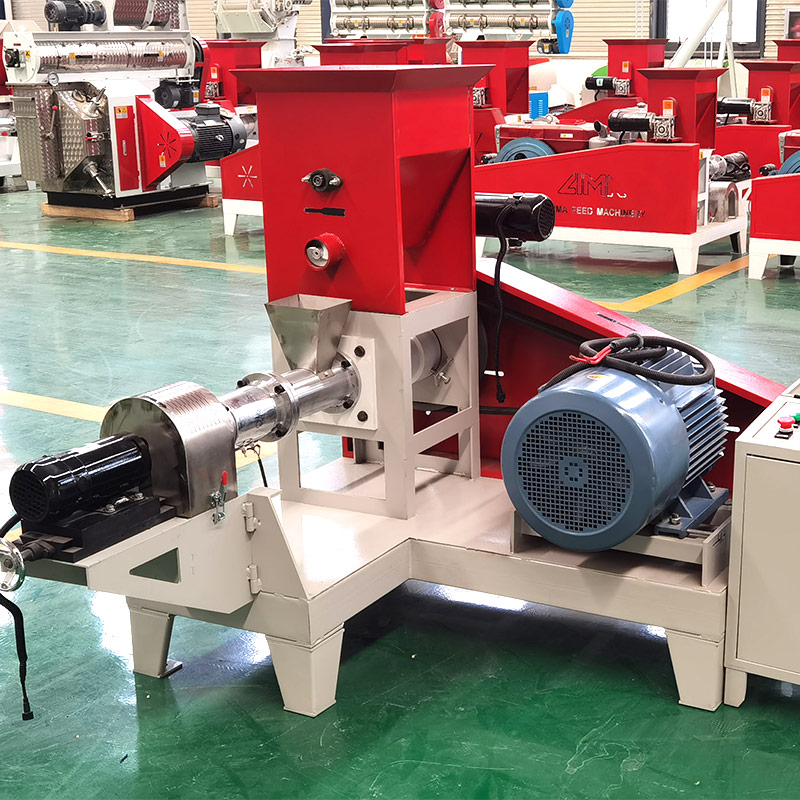

500-600kg/h Floating Fish Feed Machine By Wet way Fish Feed Extrude Machine Price

Capacity: 500-600kg/h

Pellet Size: 0.8-12mm

Energy: Electric

Application: Catfish feed, Tilapia feed, Shrimp feed, Cat feed, Dog feed

LIMA fish feed machine manufacturer

Henan Lima Machinery Co., Ltd is a leading manufacturer of pellet feed machines in China. Its floating fish feed extruder machine has been sold worldwide, including in Nigeria, Malawi, Ghana, Zambia, Cameroon, Tanzania, Pakistan, and Thailand. Clients can buy small fish feed machines, poultry food machines, and large fish feed and feed production lines to satisfy their needs.

Floating fish feed machines also called fish feed extruders, are widely used for producing high-grade aquatic feed for fish, such as catfish, tilapia fish, shrimp, crab, etc. It can also make pet food for cats, and dogs. The power supply can be divided into diesel engine feed extruder and electric engine feed extruder.

The wet fish feed extruder machine

The working principle of the wet type is similar to that of the dry type. But the former requires adding water or steam to the machine to increase the moisture to 20%, or more than 30% in the process. The purpose of the steam regulator: is to increase the temperature of the material, soften and solidify the material, and replenish the moisture of the raw material.

The wet-type fish feed pellet machine is equipped with a preparation device for maturing feed raw materials and is usually used for mass production of feed lines. It can produce neat, uniform, and beautiful ultra-small particle size particles, with good self-cleaning effect, no need to disassemble, maturity Good, high water content, wide application range, can produce high oil, high moisture materials, mainly used in aquafeed, pet food and animal feed.

Pellet sizes

Our floating fish feed machine can produce different sizes and shapes of pellets from 0.8mm-12mm by changing the molds, feeding on various stages of fish

Packaging machine

Question and Answer

1.How about the quality assurance?

Our company has been established for more than ten years. All products have passed CE and ISO9001 quality certificates. We have a professional department to test and adjust machines before shipping for you. We also have certifications in SGS, PC, and SONCAP.

2.How about the warranty?

Our warranty is one year. Our reception is 24 hours on the line talking with you. If the machine has any problems within one year, we offer repair service for free, free accessories, except for man-made damage.

3.Do we need to install the machine?

If you purchase a production line, we will have an engineer come to installation, 100 USD/engineer for one day, typically needs 2-3 engineers. We have operation instructions and videos to guide you if you buy small machines. If you still have problems, we provide professional service and teach you. We make sure your device is working very well 100%.

4.How to pay, payment method?

T/T or L/C at sight. By T/T 40% as down payment, 60% by T/T before delivery.

5.How can I know the status of my order?

We will send you photos and videos of your order at different stages in time and keep you informed of the latest information. We also can give you the shipping company website you can follow any time.

6.How do I use local materials to make the feed you do in your video?

We will provide the formula for free, and we can make the recipe based on your local ingredients, don’t worry about it.

7.Are the parts replaceable?

Parts can be replaced, so you can buy some spare parts when you buy our machine.

8.How to maintain the fish feed machine?

In fact, you need to clean the screw and cutter parts after each work, so that the machine is not prone to problems with regular maintenance.

9.I don’t know the capacity, how to calculate my capacity?

If you buy ten 25kg bags of feed a day, you need 250kg a day.

10.Shrimp, cats, and dogs can all be made with a fish machine. What are they made of?

The same machine can produce different feeds. It only needs to change the mold and related raw materials.