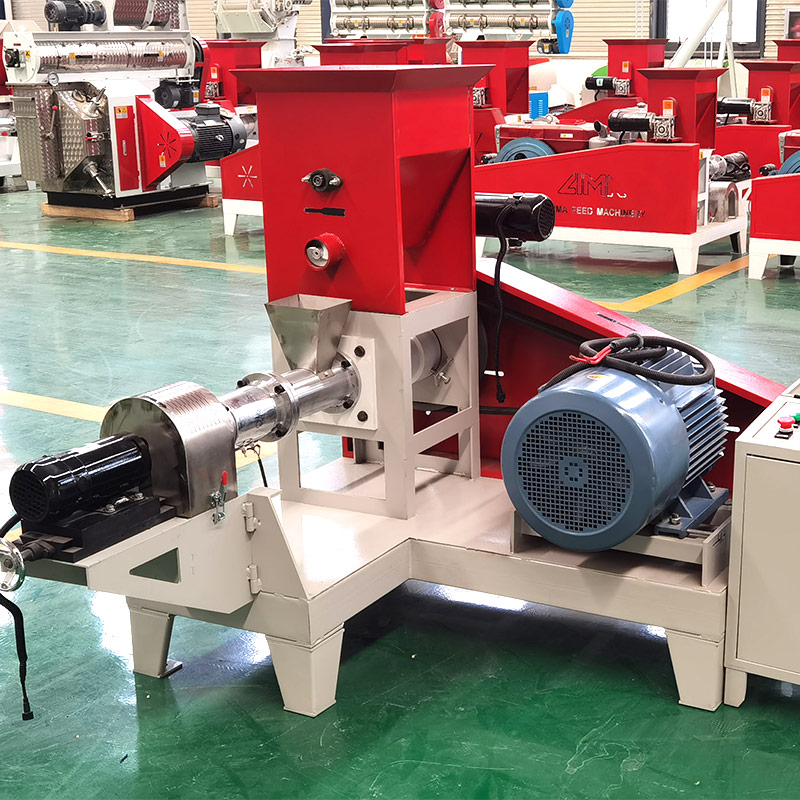

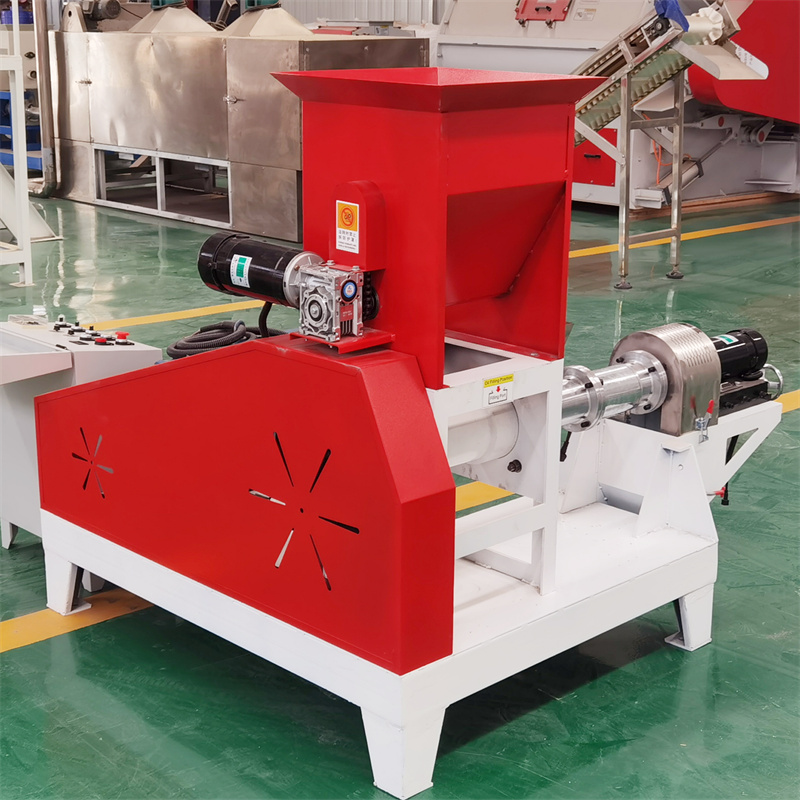

100-150/h Dry Floating Fish Feed Pellet Production fish feed Processing Making Extrusion Extruder Machine

Model :LM60

Capacity (kg/h):100-150kg/h

Main power (kw):15kw

Feeder power (kw) 0.4kw

Screw Diameter (mm):Φ60

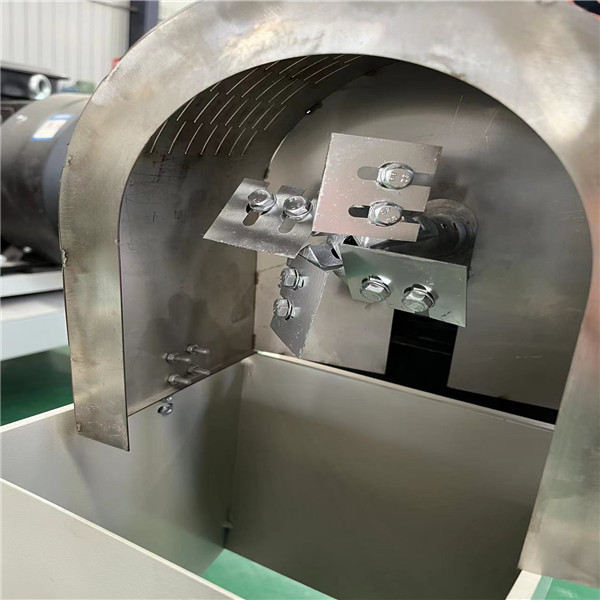

Cutter power (kw);0.4kw

Machine size (mm): 1470*1100*1250

Weight (kg):350

Machine Feature

1. Extrusion processing is a processing technology that passes raw materials through high temperature, high pressure, and instant maturation, and integrates conveying, crushing, extrusion, mixing, shearing, high-temperature sterilization, and molding.

2. It can process viscous, high fat, and high moisture raw materials.

3. Good water resistance, the aquatic feed pellets can be very stable in water. Whether it is a soaking feed or a floating feed, it can be kept from immersion in water for 12 hours, which can maintain the water quality of the culture and reduce the waste of feed.

4. Higher digestibility. The digestibility of starch, protein, and the like is improved, and the strong extrusion can degrade some of the compact cellulose and keratin proteins so that the digestibility is greatly improved.

5. Excellent palatability. The finished puffed particles have the characteristics of porous and uniform texture, and produce partial aroma substances, which increase the feeding traits of the feed, stimulate the appetite of the aquatic animals, and increase the feed intake.

6. Broaden the scope of raw material utilization. The twin-screw extruder can enrich the feed resources by processing excess water, grease or cellulosic material into other forms of aquatic products.

Product Parameter

| Model | Capacity (kg/h) | Main power (kw) | Feeder power (kw) | Screw Diameter (mm) | Cutter power (kw) | Machine size (mm) | Weight (kg) |

| LM40 | 30-40 | 5.5 | 0.4 | Φ40 | 0.4 | 1400*1030*1200 | 220 |

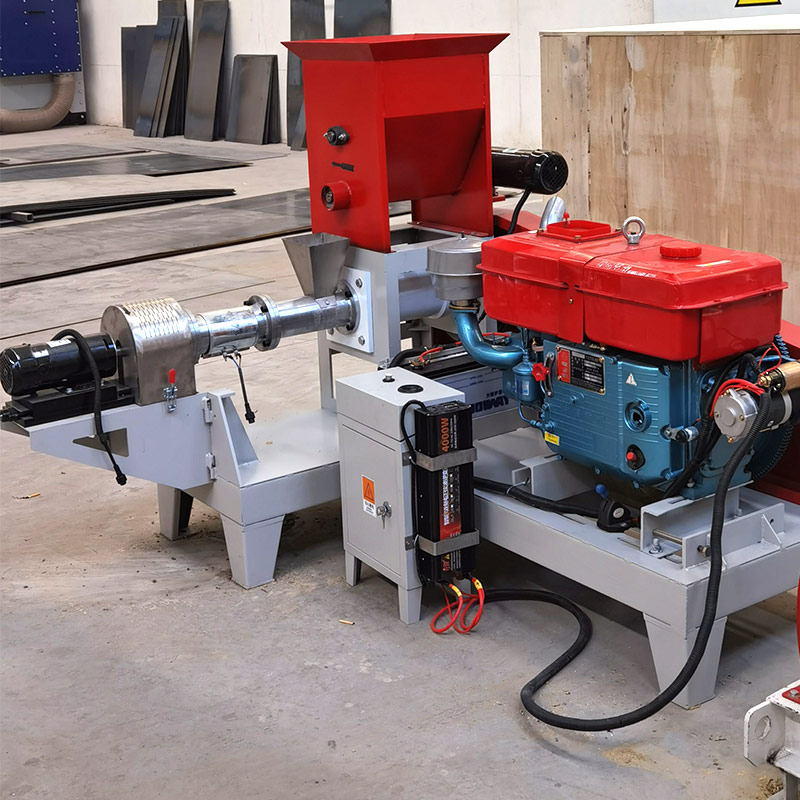

| LM40 -Diesel | 30-40 | 12HP | 0.4 | Φ40 | 0.4 | 1400*1250*1200 | |

| LM50 | 60-80 | 11 | 0.4 | Φ50 | 0.4 | 1470*1100*1250 | 320 |

| LM50-Diesel | 60-80 | 18HP | 0.4 | Φ50 | 0.4 | 1660*1170*1050 | 540 |

| LM60 | 100-150 | 15 | 0.4 | Φ60 | 0.4 | 1470*1100*1250 | 350 |

| LM60-Diesel | 100-150 | 25HP | 0.4 | Φ60 | 0.4 | 1470*1120*1250 | |

| LM70 | 180-200 | 18.5 | 0.4 | Φ70 | 0.4 | 1650*1400*1300 | 580 |

| LM70-Diesel | 180-200 | 30HP | 0.4 | Φ70 | 0.4 | 2060*1450*1300 | |

| LM80 | 200-300 | 22 | 0.6 | Φ80 | 0.6 | 1800*1450*1300 | 695 |

| LM80-Diesel | 200-300 | 35HP | 0.6 | Φ80 | 0.6 |

10 different formula as follow

1, corn meal 50%, wheat middling flour 12%, flour 10%, soybean meal 3%, rice flour 5%, meat 20%.

2, corn meal 55%, wheat middling flour 10%, flour 5%, puffing powder 20%, soybean meal 3%, meat powder, 5%, animal fat 1.5%, salt 0.5%.

3, wheat middling flour 15%, rice shell powder 10%, soybean meal 20%, rapeseed meal 16%, and cottonseed meal 8%, and corn meal 5%, fish meal 5%, flour 25%.

4, corn rice meal mixture 20%, flour 25%, bran 5%, soybean protein 20%, fish meal, rapeseed meal 16%, cottonseed meal 8%.

5, corn rice meal mixture 17%, flour 25%, bran 5%, soybean protein 20%, fish meal 9%, rapeseed meal 16%, cottonseed meal 8%.

6, corn rice meal mixture 11%, flour 25%, bran 5%, soybean protein 20%, fish meal 15%, rapeseed meal 16%, cottonseed meal 8%.

7, corn meal 52.8%, bran 22.5%, soybean meal 17.5%, fish meal 3.5%, bone powder 1.2%, trace element 1.5%.

8, corn meal 60%, soybean meal 10% , bran 17%, cottonseed cake 10%, calcium hydrogen phosphate 2%, additives 1%.

9, corn meal 50%, soybean meal 28.7%, calcium hydrogen phosphate 2%, stone meal 1.3%, meat powder, 3%, premix 15%.

10, corn meal 65.9, soybean meal 16%, bran 12%, fish meal 3.2%, calcium hydrogen phosphate 1.4%, premix 1.5%.

Raw materials can be added to table salt, and seasoning oil.

The moisture of raw material is between 15%-18%.

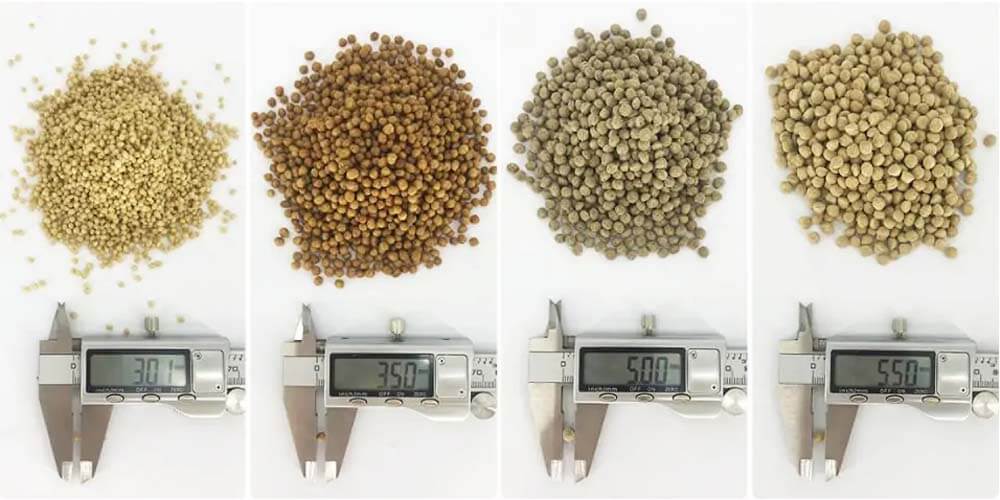

Floating fish feed machine Final Products