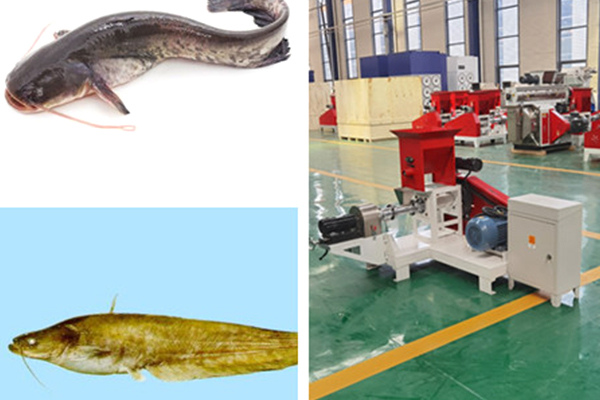

Sinking Fish Feed Pellet Machine

Working Principle Of Sinking Fish Feed Pellet Machine. Heating the materials by the frictional force, this Sinking fish feed extruder machine squeezes raw materials out of the holes of the mold under the action of screw extruder.

Feed extrusion process description – SciELO

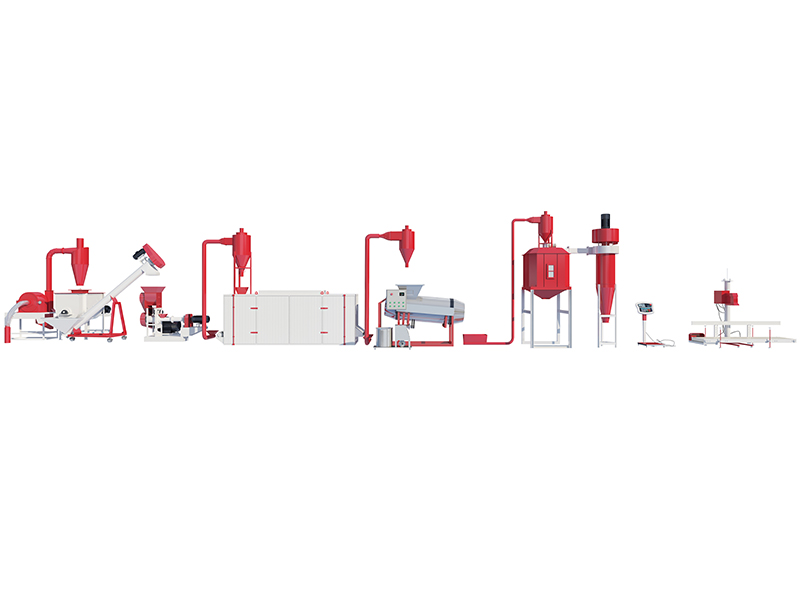

The following work discusses the main features of feed extrusion process explaining the expected effects on the final product according to the raw material used as starch, protein, fat and fiber. The selection of processing equipments as feeder, preconditioner and extruder is discussed considering the involved costs and the probability of

Abstract- Index Terms- IJSER

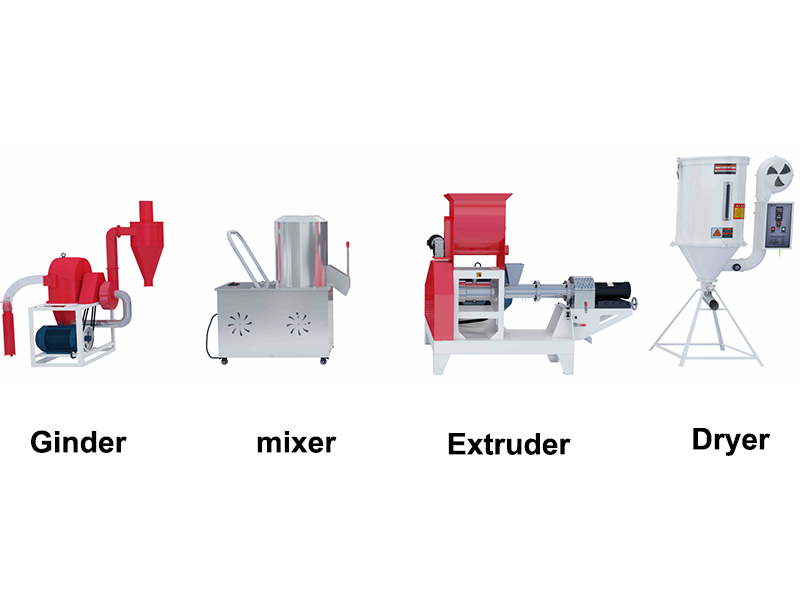

Fish feed extruder comprises of hopper, a barrel which houses, the screw conveyor, the cutting knife, the die, a heater etc. It can be divided into wet and dry type mill. They both can produce floating fish feed pellets, slowing sinking pellets and sinking feed pellets.

Single Screw Wet Type Fish Feed Extruder for Floating Pellet

Working Principle of Wet Type Fish Feed Extruder Machine. Fish feed extruder can also be named as technological process, it forces raw materials into one or more of following process such as mixing, heating, pasting, cutting, extruding, etc. flow through the die, making material eruption gasification. Diameter of the holes which decide the

Wet Type Fish Pellet Extruder for Large – Fish Feed Extruder

Working Principle of Fish Feed Pelletizer The heart of the extruder machine working is: preconditioning, cooking and die shaping. With boiler continuously providing hot steam into the conditioner, mixed materials from fish feed mixer can be fully cooked and the nutritional value is improved.

floating fish feed pellet mill/animal feed extruder machine

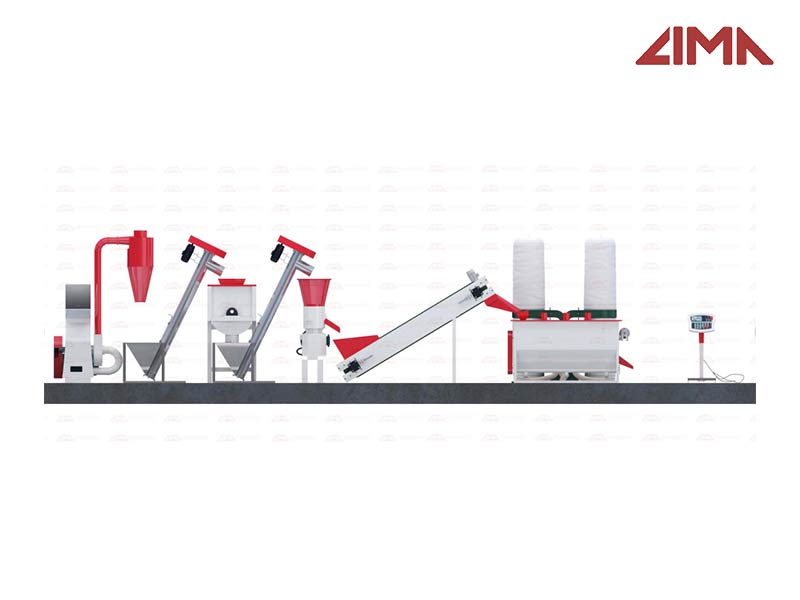

Oct 10, 2017 · electric pellet machine is frequently driven by diesel engine or electric motor.Diesel feed pellet mill is energy saving pellet machine for making feed for animals such as feed for rabbits, fish, chicken, pigs, sheep, cattle, etc.A variety of raw materials like all grains such as corn, broomcorn, barley and wheat,etc.can be processed into feed pellets.Feed pelletizing process is easy in

Wet Type Fish Feed Extruder for Fish Feed & Pet Food

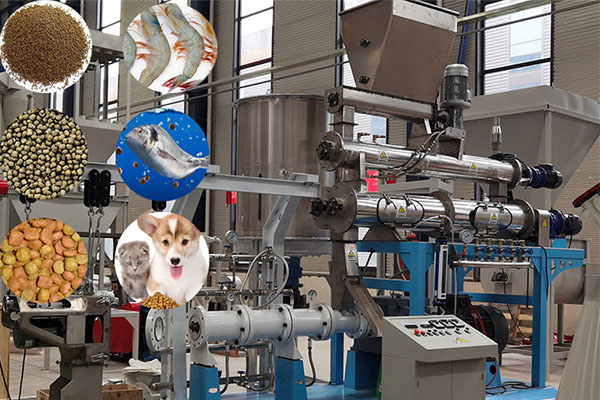

1. Fish feed extruder can produce fish feed pellets for fish, eel, shrimp, crab, loach, bullfrog, etc, and can produce many kinds of pet feeds for cat, dog, and etc. 2. It is mainly employed in medium or large size feed processing factory and aquaculture farm. 3. The raw materials can be wheat, soybean, cake and other leftovers etc.

Fish feed extruder machine – Yongfeng Machinery Equipment

Extruder machine is widely used for processing of kinds of aquatic , pets feed pellets, such as floating, sinking fish feed, frog feed, dog feed, cat feed, and etc. Features and Advantages Working principle:

Wet Type Fish Feed Extruder – Pellet-Richi.com

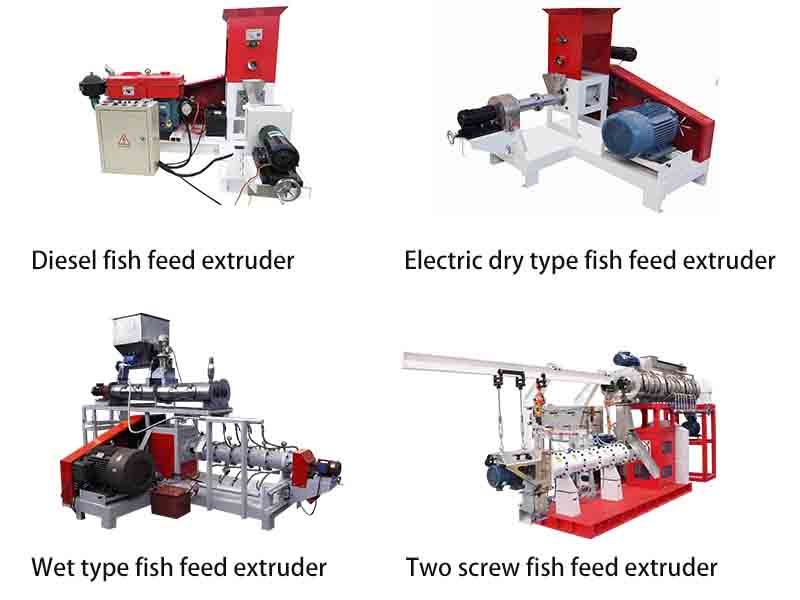

Working Principle The material in the extruding chamber of the fish feed making machine is subject to high pressure and temperature, making starches gelatinize and denaturing the protein, so that to improve the water stability and digestibility of feed pellet. Meanwhile salmonella and other harmful bacterium are killed in the process.

Extrusion Cooking Technology for Foods: A Review

Extruder feedrate depends on the types of screw element, screw speed, type of feeding element and feed moisture. The federate has an influence on residence time, torque requirement, barrel pressure and dough temperature. 2.2 Feed Ingredient Variables Feed composition, moisture content and particle

Hot sale dry type floating fish fodder extruder

Working Principle of floating fish fodder extruder The machine has a pair of screw and screw nut, which is used for mixing and rolling. The material runs into the extruding chamber, and is extruded between screw and screw nut, rubbed, cut. At the same time, the pressure and the temperature go up sharply during 3-7s.

DGP Dry Type Fish Feed Extruder

7.The fish feed pellets are more economical than the compound powder feed. Working Principle. 1. During extruding process, material feed from the end of machine cavity convey to the whole cavity by screw, then divided into several regions at extruded part, each region have a ring (press ring. to control flow and press.

Fish Feed Crusher for Feed Grinding – Fish Feed Extruder

Fish Feed Crusher Working principle 1. The raw material enters into crushing chamber through feed hopper and is held there until it is reduced to the size of the openings in the screen, and there are flailing hammers spinning very fast and close to a perforated screen. 2.

Twin Screw Extruder Main Components And Working Principle

The process of melt extrusion is to pre-mix good material from the feed port into the extruder barrel, the first paragraph of the barrel for the feed section, the material will not melt at this stage, with the screw drive, the material was brought into the second The section is the compression section, the section is the heating stage, the

Fish Feed Extruder-an Economical Production Machine for Fish

Here the most important processing is extrusion puffin, there are two type fish feed extruder: Dry type fish feed extruder and Wet type fish feed extruder. The Working principle: The materials were processed from the hopper into the crushing chamber, hit by the high-speed rotating parts then break down, and change the motion direction of the