Single Screw Feeders – Coperion

Reliable feeding of free flowing bulk materials Single screw feeders are ideal for feeding free flowing bulk materials such as pellets and powders. The S500 single screw feeder is available as a volumetric unit or as a gravimetric unit with a three-point suspension scale.

CPF Fish Feeds – CP 9910S 2 MM Floating Fish Feed

Authorized Wholesale Dealer of CPF Fish Feeds – CP 9910S 2 MM Floating Fish Feed, CP 9951 4mm Floating Fish Feed, CP 9911 4 MM Floating Fish Feed and CP 9952 6mm Floating Fish Feed offered by Feed Wale, Bhiwandi, Maharashtra.

STS Mc¹¹ Compounder – Coperion

High manufacturing precision, only 2 mm clearance between side feeder screws and twin screws of STS Mc 11 Feed hopper in quick-change design The feed hopper is simply clamped to the inlet barrel and can be quickly removed by loosening the bolts.

Fish Farming – British Aqua Feeds | Bulk Feed Supplier, Bait

Feed Pellets available by the sack or bulk by the tonne from the leading manufacturers including Coppens and Skrettings, various sizes, Hi-OIl, Low-Oil, Carp & Coarse Pellets are the perfect feed for either rearing on fish (Farming) or for actual fishing bait. They

Extrusion of fish feed – Engormix

8/12/2016 · I need help on extrusion of fish sinking feed .I reach 50:50 of sinking and i need 99 % but i just can not make feed to sink is it from formulation or from adjustments of the extruder. Hi Denis. Which type of extruder you use? Generally, formula should be suitable for

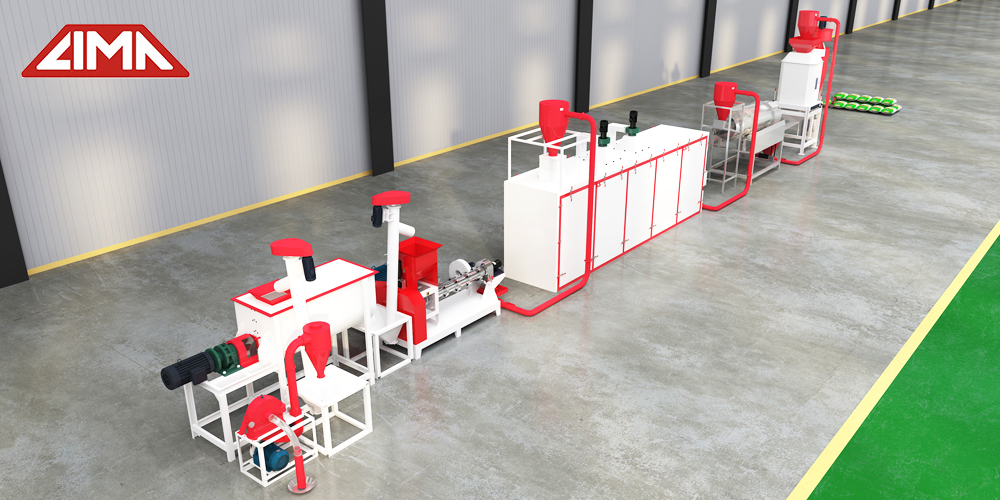

High Productivity Fish Feed Extruder Production Line

27/4/2017 · CONTACT US:HAIHUANG INDUSTRIAL ZONE, MIDDLE SECTION OF ANLIN RD,ANYANG,HENAN,CHINA.Phone: +86 372 5368865Cell/whatsapp/wechat: +86 186 3723 8677Fax: +86 372

(PDF) Extrusion technology and its application in food

mm) extruders had a higher retention rate of B vitamin group (44–62%) compa red to 20% for long barrel extruders (Athar et al and dried. Feed for ornamental fish, h igh-grade complete feeds …

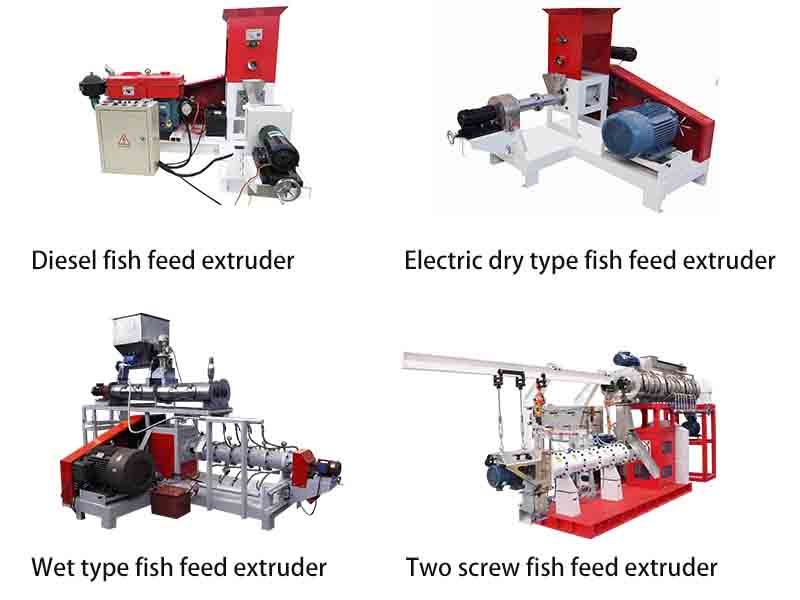

Fish Feed Extruder – YouTube

6/7/2011 · Our Dolly Extruder Can produce Floating Fish Feed (50 Kg/Hr) as well as sinking feed (80 Kg/Hr). For more information Please Contact us at in_unitech@yahoo.c

Entek Extruders

ENTEK’s twin-screw extruders are designed for maximum flexibility. Taking full advantage of co-rotating technology, ENTEK’s screw geometry, metallurgy and manufacturing discipline allow for industry leading material mixing and productivity in multiple areas of processing.

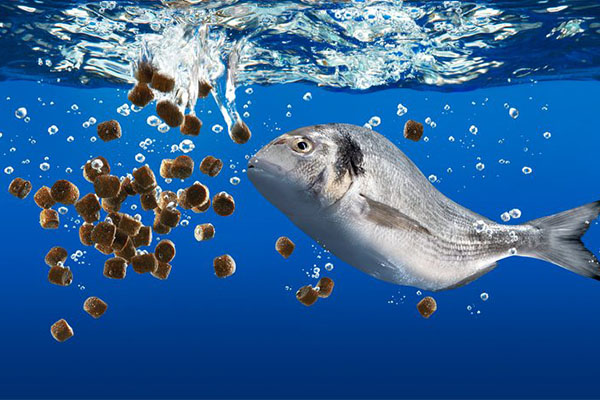

2mm Marine Sinking Pellet – Frenzy Fish Feeds

2mm Marine Fish Food – Sinking Pellets Get the best possible start for your marine fish! These highly nutritious premium commercial grade pellets are specifically designed to promote ideal health and supply the perfect balance of nutrients and essential compounds needed to ensure fish are healthy and strong. These pellets are Australian made, factory formulated []

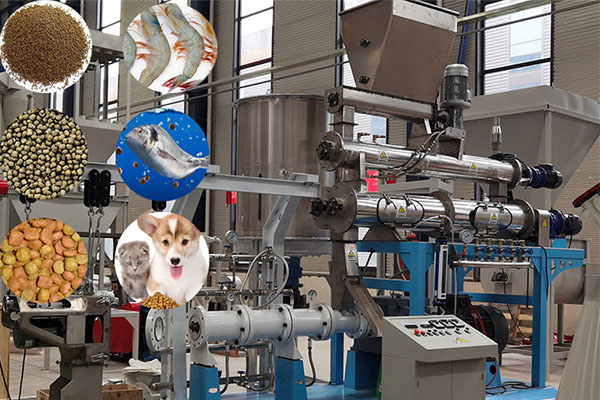

Floating Fish Feed Extruder Machine Price For Extruding

7/4/2019 · this type of floating fish feed extruder machine belongs to wet method type feed extruding machine for kinds of fish, which is specialized for big production capacity and big feed production factory, we also have another type of fish feed pellet machine for home use and small farm use.as per your requirement,you can choose to produce how much big of finished floating fish feed pellets. our

2 – Weebly

Fish meal is the main protein source in aquafeed, but supply is limited, which means that alternative sources must be used. From a processing point of view, extrusion is the most efficient way of turning plant protein into fish feed. Twin-screw extruders offer a

2mm Tropical Fish Food Small Sinking Pellet – Colour

Tropical Fish Food 2mm Sinking Pellets Get the best possible start for your tropicals! Perfect for Aquariums. These highly nutritious premium commercial grade pellets are specifically designed to promote ideal health and supply the perfect balance of nutrients and essential compounds needed to ensure fish are healthy and strong. These pellets are Australian made, factory []

Performance Evaluation of Floating Fish Feed Extruder

extruders include the temperature, mass, resident time, pressure and shear rate depending on extruder geometry, process parameters and raw material composition [1]. According to [2], process parameters like the type of extruder, length of barrel, feed rate

Food Extruder Africa | World-Class Food & Feed

As the leading manufacturer of twin-screw food extruders in Africa, our vision is to become the supplier of choice for extruders in Africa and then the world. Our mission CFAM Technologies (Pty) Ltd developed from a research project in 1998 to an established extrusion technology company that designs and manufactures world-class food and feed processing plants and equipment.