Floating Fish Feed Extruder Machine Price For Extruding

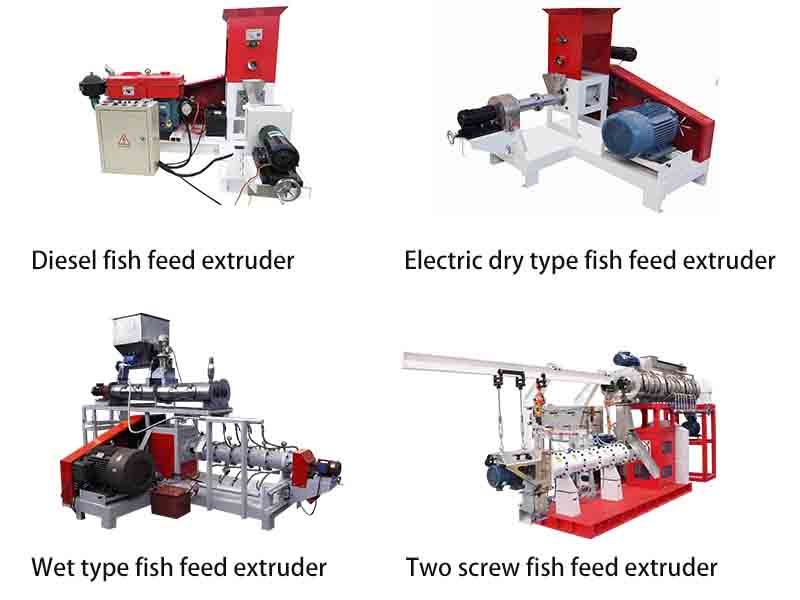

this type of floating fish feed extruder machine belongs to wet method type feed extruding machine for kinds of fish, which is specialized for big production capacity and big feed production factory, we also have another type of fish feed pellet machine for home use and small farm use.as per your requirement,you can choose to produce how much big of finished floating fish feed pellets. our

FISH FEED FORMULATION AND PRODUCTION

1 Dietary nutrient levels recommended for clear water aquaculture systems 2 Starter: 0–5g fish, Fingerling: 5–50g fish, Production: 50–250g fish 3 Amino acid requirement based on the essential amino acid composition of fish 4 Fish:plant lipid ratio of 5–7:1 5 Suggested dietary vitamin levels taking into account processing, storage and leaching losses.

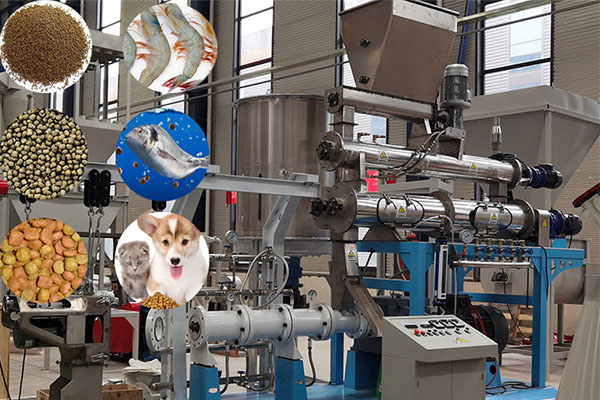

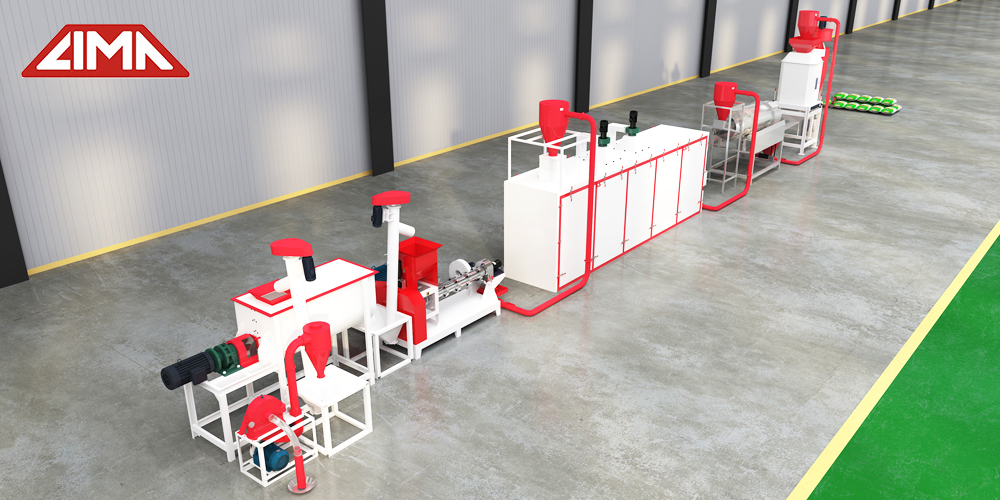

Aquatic Feed Extruder to Process High Quality Feed

Pellets expanding degree is closely related to modulation conditions, operation process and feedstocks moisture content. 2.2 Option of Floating Feed or Sinking Feed For fish farmers, how to choose the suitable fish pellets is crucial. In fact, the options of loating

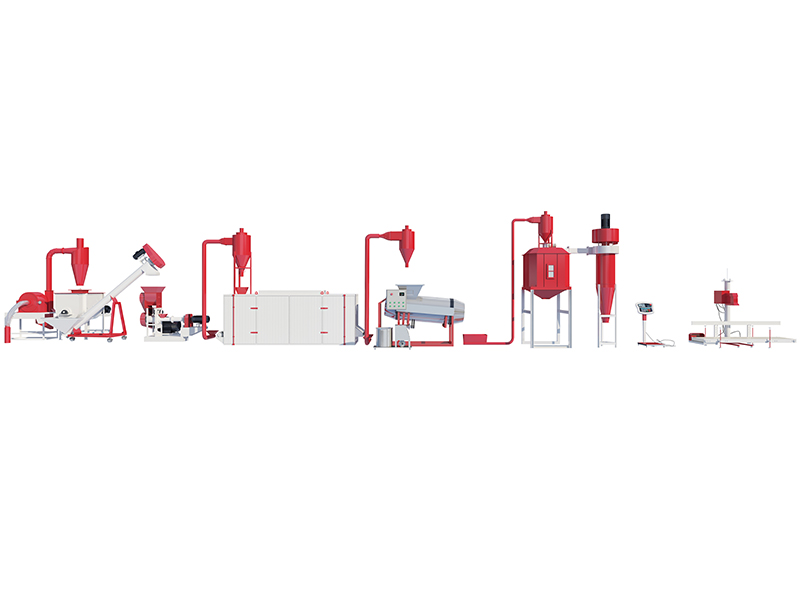

Aquafeed Processing Technology and Equipment – Fish

As a deep processing step in feed processing, the pelleting processing technology design and the choice of related machines are important factors affecting the quality of aquatic feed, including tempering and extruding technology.

Commercial fish feed | Aquaponics Wiki | Fandom

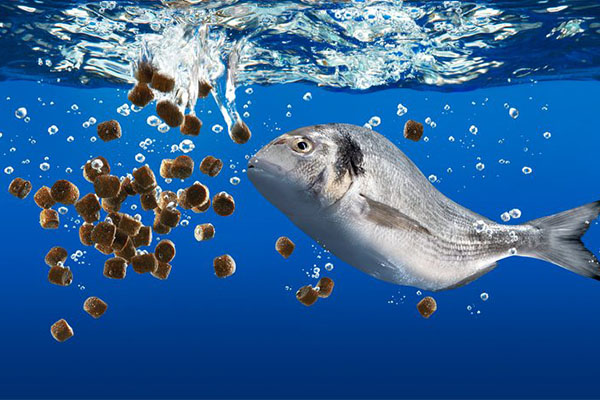

Manufactured feeds are an important part of modern commercial aquaculture, providing the balanced nutrition needed by farmed fish. The feeds, in the form of granules or pellets, provide the nutrition in a stable and concentrated form, enabling the fish to feed efficiently and grow to their full potential. Many of the fish farmed more intensively around the world today are carnivorous, for

Commercial fish feed – Wikipedia

The Pelleting Process – CPM

This machine is usually located on the ground or main work floor level. The hot, extruded mash (pellets) flows by gravity into a cooler (Figure 1, Item 3) where it is held for three to six minutes while being cooled and dried by a flow of air. The air is drawn through

Pellet Fish Feed, Extruded Fish Pellet Feed

The production of feeds is an important part for fish farming, because it provides the balanced nutrition that the farmed fishes need. Fish feeds can be various forms, and the granule or pellet fish feed supplies fishes with nutrition in a stable and concentrated mode, which benefits feeding efficiency and fish

Pelletizing – Wikipedia

Iron ore pellets are spheres of typically 6–16 mm (0.24–0.63 in) to be used as raw material for blast furnaces.They typically contain 64–72% Fe and various additional material adjusting the chemical composition and the metallurgic properties of the pellets. Typically limestone, dolomite and olivine is added and Bentonite is used as binder.

Small Animal Poultry Feed Pellet Machine Farm Use

Small animal poultry feed pellet machine is a great choice for small feed pellet plant, livestock, poultry, fish farms and also individual use. Feed pellets it can make for cattle, sheep, goat, chicken, duck, geese, fish, pig, horse, etc. Raw materials applicable to corn

Extrusion Technology – Coperion

One key benefit of Coperion’s twin screw extruder series is the consistency of important parameters which ensure the reliable scale-up from lab extruders to production scale. Both the diameter ratio D o /D i which determines the free volume of the twin screws in the process section and the specific torque are constant respectively for all sizes of our extruder series.

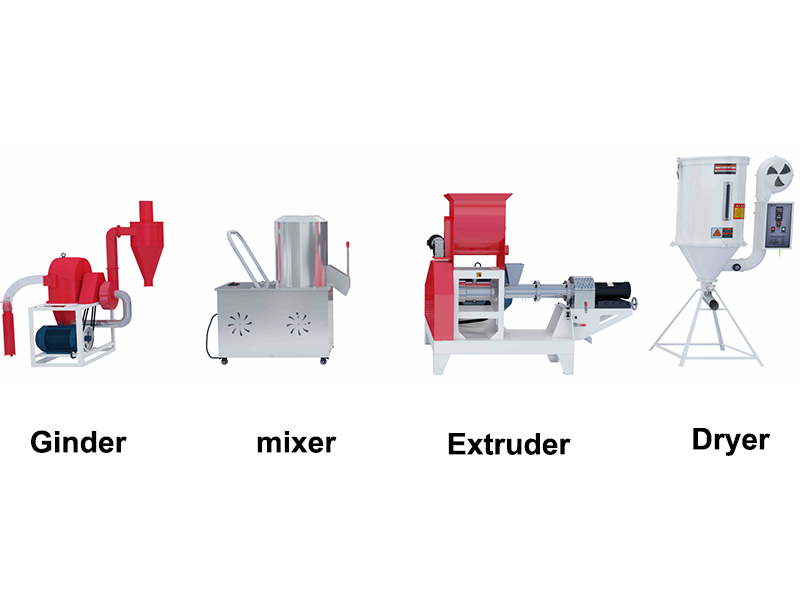

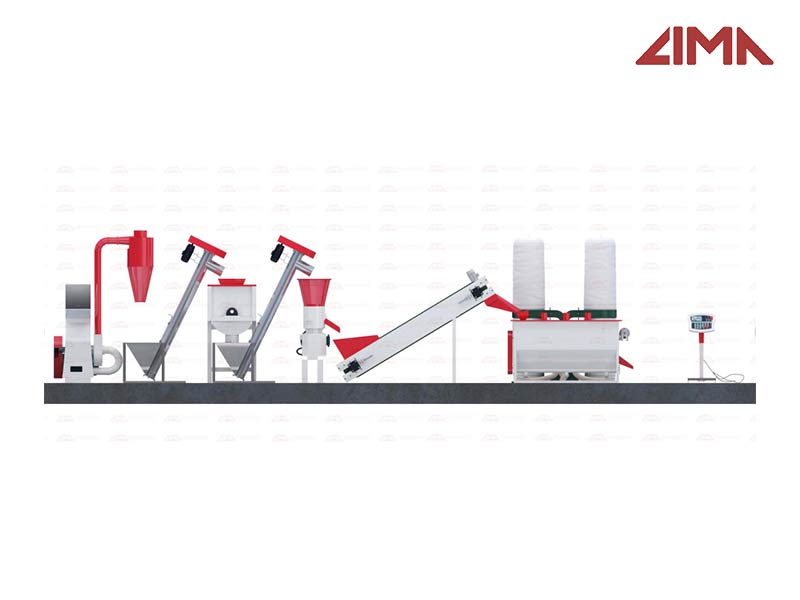

Animal feed manufacturing process – Animal Feed

Feed pelletizing machine is the key equipment for feed making. Feed granulation machine is a ring mold design, widely used in the production of large-capacity feed particles. Step 05: Feed Pellets Cooling Process High-temperature, high-humid feed pellets

(PDF) Feed Processing Technology – ResearchGate

PDF | On Jan 1, 2003, Gowri Naidu Reddy and others published Feed Processing Technology | Find, read and cite all the research you need on ResearchGate EFFECT

Feed Pellet Coating Machine—Advanced Feed Pellet

The pellets coating machine adopts excellent post-addition technology, which can spray nutriment and medicine on the formed pellets surface. You can add oil and fat, zymin, vitamin, organic acid and microorganism etc.It is an important machine for feed pellets

Chapter 18 Fish Feed Production, Storage and Transportation

The most important feature of the pellet is durability, crushing strength and water-resistance. The following factors ensure the stability of a grain: – solid adhesive medium, e.g., powdered milk, sugar, or carbamide, developed by steaming or heating of starch