(PDF) Physical and Mechanical Properties of Fish Feed

The water stability of pellets of fish feed value ranged from 54.15 to 91.78%. The repose angle of pellets fish feed value ranged from 27.00 to 38.00°. The crushing load of pellets fish feed

Food waste-based pellets for feeding grass carp

10/3/2020 · The price of each feed pellets ($/ kg feed, in US dollar) was calculated using the price obtained from the supplier. Economic analyses were conducted according to Hien et al. (2015) . Briefly, the cost for producing 1 kg fish ($/ kg fish) was obtained by multiplying $/ kg feed with FCR obtained from the experiment.

Virgin microplastics are not causing imminent harm to fish

1/5/2018 · The retention rate of microplastics in the gastrointestinal tract was very low (). 24 h after the last feeding the average number of microplastic particles in the fish intestines and stomachs ranged between 0 and 34 for all plastic types.

Floating Fish Feed and Ingredient Selection

After coating, these products contained 22% fat and 35.5% protein 494 g/l product density 750 g/l product density. Processing Effects on Proteins: Wet Chemistry Methods. 1) Denaturation of Proteins. – Begins to occur at 55°C ( 130°F) – Measure PDI (Protein Dispersibility Index) digestible in acidic environment.

Products & Species | BioMar

Feed for aquaculture is a concentrated package of nutrients and energy designed to provide rapid, healthy and cost-effective growth, and prime quality end products. Through the BioMar Retention Technology (BRT) project we have learned that process conditions in the feed production itself have a very strong impact on the feed’s structure and physical properties.

Fish larval nutrition and feed formulation: knowledge gaps

The lowest rate of fish with malformed vertebrae was found in fish fed PK at 1 mg kg −1 (50.7%; 51.4%) and 100 mg kg −1 (47.3%, 55%), and MSB at 25 mg kg −1 (53.6%; 54.8%), whilst significant larger incidences were observed in fish fed with MSB

(PDF) Feed Processing Technology – ResearchGate

From the Pareto Chart generated using the values obtained in the fractional factorial analysis, only these two factors exceeded the 0.1195 basis of the extent of the effect of the parameter at 90%

Trout | BioMar

A strong focus on feed performance and the total economic performance of fish farming has over the last 50 years made BioMar the preferred choice for trout farmers all over Europe. As the leading expert on trout nutrition, we use our knowledge of nutrition, retention, and digestibility of raw material components to produce our high quality feed.

ng o f F o o ec Journal of Food Khater, et al. J Food Process

area of pellets fish feed value ranged from 10.57 to 71.13 mm2. The volume of pellets fish feed 4.04 to 79.09 mm3. The weight of 100 pellets value ranged from 0.11 to 5.51 g. The bulk density of pellets of fish feed value ranged from 267.11 to 711.35 kg m-3. The

Chapter 9. Ingredients for Fish Feed Manufacture in the

Published data from research in poultry and swine nutrition show corn or wheat as the predominant dietary component and soybean meal or fish meal as the only dietary protein source in test diets. Often a test ration would consist of just a cereal grain and soybean meal plus mineral and vitamin supplements.

Effects of extruded pellet and moist pellet on growth

Feeding trial was conducted in a semi re-circulating system with 250-L aquaria each having a water flow rate of 1.5 L/min. Supplemental aeration was provided to maintain dissolved oxygen near saturation. Water temperature was maintained at 21 ± 1 °C (mean ± SD). Salinity was maintained at

Chapter 15. Fish Feed Formulation

Next, the protein level of the feed is subtracted from that of the feedstuffs, placing the answer in the opposite corner from the feedstuff. Ignore positive or negative signs. To make the 27 percent crude protein carp feed, we must mix 17/35.8 of rice bran with 18

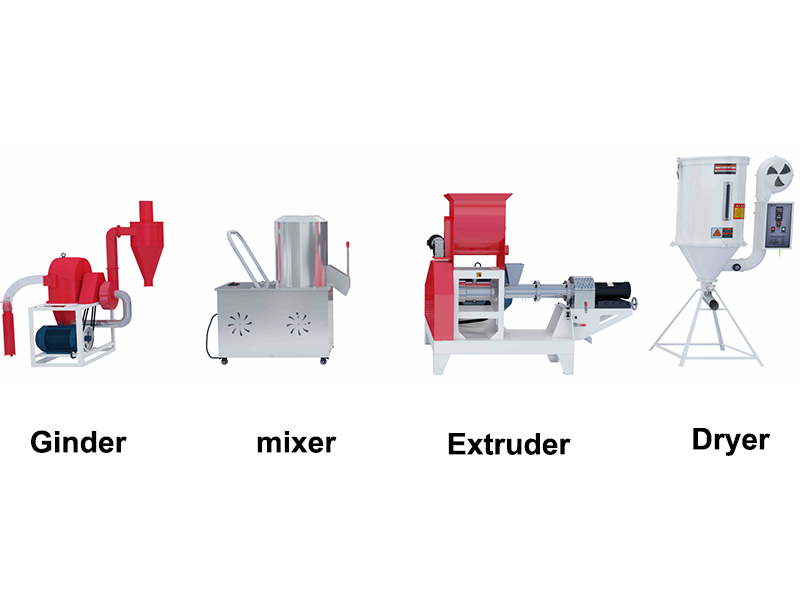

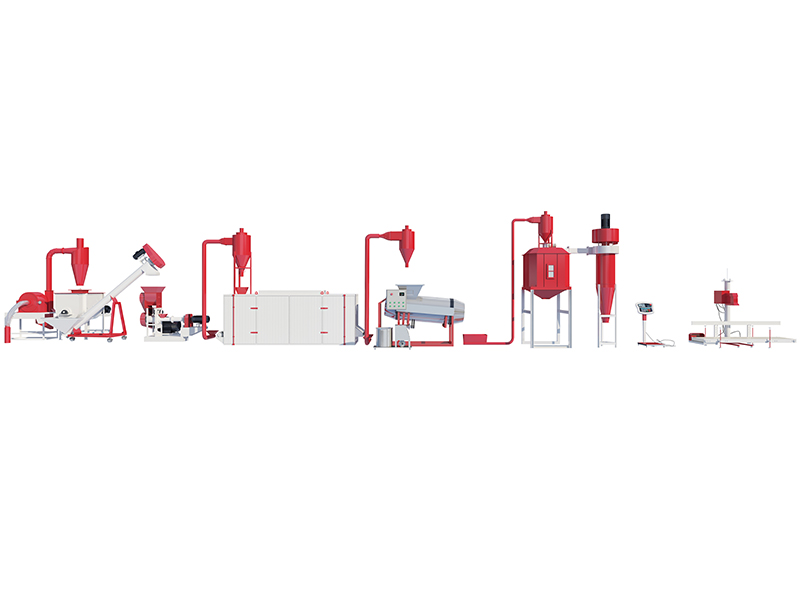

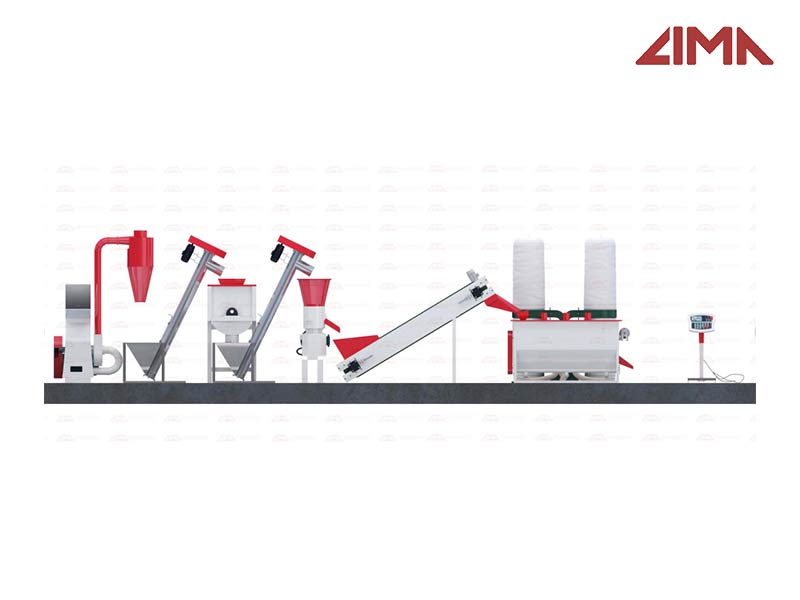

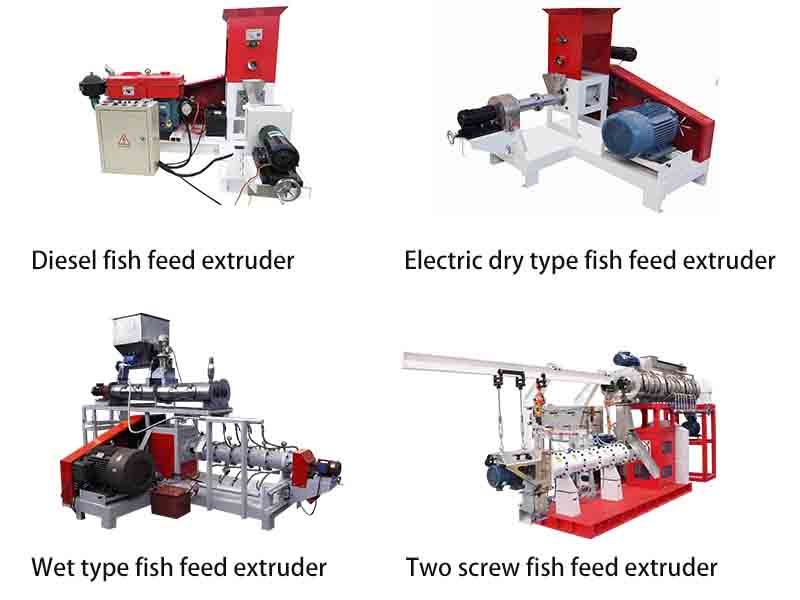

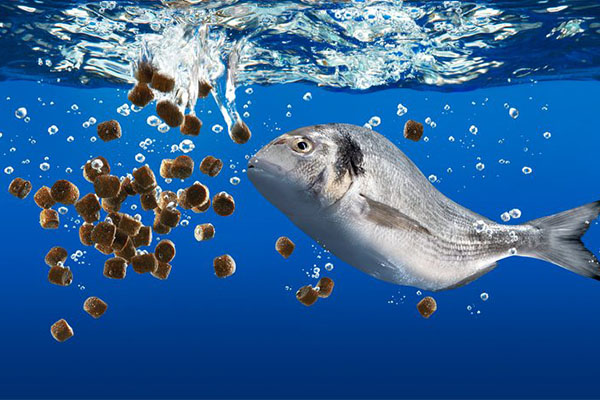

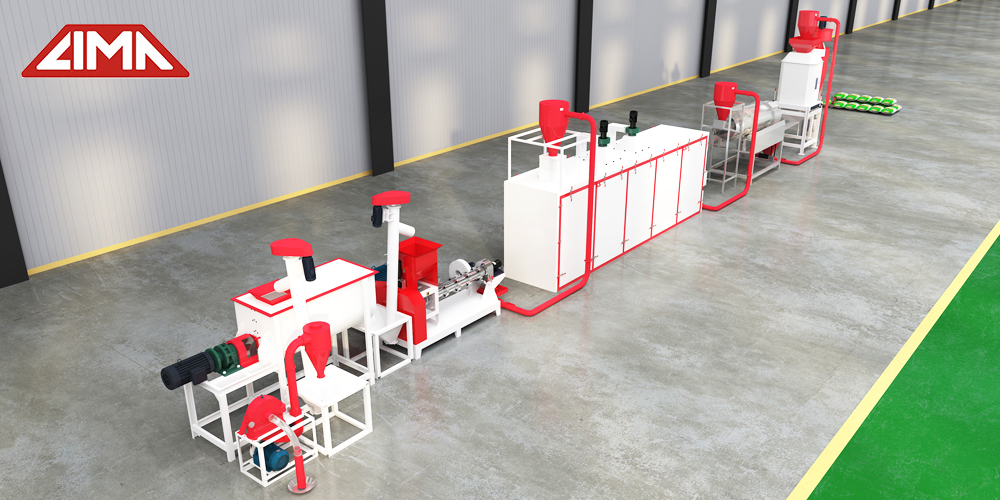

Small Floating Fish Feed Machine Price, Capacity 60-400kg/h

• High Nutrition Retention – Floating fish feed stays on the water for a long time. When the feed is dissolved in water, it will lose some nutritional value. Floating fish feed can reduce the loss of materials caused by water, mud and waste by about 20%. Good

Feeding pelleted rations – Department of Primary Industries

The break-even value = (value of grain × ME of manufactured feed) ÷ ME of grain Roughage – needed for digestion A manufactured feed or pellet may be a complete ration, but the more finely it has been processed, the less roughage it contains.

Floating Fish Feed Production Process-Fish Food

High Nutrition Retention – Floating fish feed can stay on the water for a long time. When feed is dissolved in water, it loses some nutritional value. Floating fish feed can save about 20% of material loss due to water, mud and waste. High-quality fish feed floats on the water for at least 10 hours.