Feeding Technology – Coperion

With over 100 years of experience in feeding technology, Coperion K-Tron development and engineering teams are experts at creating smart feeding solutions. Material Challenges Our customers are a diverse group of global industries.

PREPARATION OF FISH FEED – FAO

PREPARATION OF FISH FEED • Examples for changes of nutritional value (especially crude protein) of ingredients according to exported / imported countries • Fish meal and soybean meal are the main protein sources of the fish feed • Fish meal: 65-67% from Peru, 65% from Chile, 67-72% from Norway, 68-70% from Denmark, 71-72% from Turkey.

Commercial fish feed – Wikipedia

In the current technology, fish feed extruders play a key role in production lines. Although the majority of the process of the fish feed production occurs in the extruder, grinding and mixing can highly affect the quality of the final product. Water is added and the resulting paste is extruded through holes in a metal plate. The diameter of the holes is usually the most important parameter that sets the diameter of the pellets, which can range from less than a millimetre to over a centimetre.

5.0 MANUFACTURED FEEDS FOR AQUACULTURE

The world’s feed manufacturing industry, which has its origins in the western industrialized countries, arose from the need to supply large quantities of meat products for urban consumption. The industry initially provided simple services to farmers such as grinding of coarse grains and blending fodders in the proportions dictated more by available supplies than by needed balance of nutrients in the final mixtures. As the demand for animal products increased, new methods for their production became necessary. It soon became apparent that such production could only be achieved by adoption of intensive animal husbandry, whereby traditional feeding methods had to be replaced by more efficient ones based on new knowledge concerning the nutritional requirements of farm animals for growth and production. This new knowledge, together with the discovery that farm animals responded well to diets containing a wide variety of food grains and agricultural by-products, provided basic dietary nut See full list on fao.org It is widely recognized in the feed manufacturing industry that steam conditioning is of vital importance in pelleted feed production. The use of steam Under normal operating conditions involving a single horizontal barrel-type steam conditioner, mash transit time is brief – between 5 and 20 seconds. During this short period, liquids such as molasses or fats that are added may not be absorbed sufficiently to prevent their interference with the subsequent pelleting process. Excess water (from added molasses) may “choke” up the die causing interruption in pellet production. Excess unabsorbed fat results in production of soft pellets with low durability. To overcome these effects, recent developments have centred on providing greater retention time of feed that include high levels of added liquids in the conditioner. Two new processes have been proposed (Carmichael, R.Q., 1981). One describes a long term conditioning process involving retention of feeds in a ripening kettle. The other,… See full list on fao.org Feed cost represents 40 to 60 percent of total operating cost in intensive aqua-culture. For a fish farm to be profitable, feed cost should not exceed 20 percent of the farm-gate value of the product if the feed used is the dry type, and not more than 10 percent if moist type pellets are employed. Typically, a ton of dry pelleted feed, based on conventional ingredients, in a developing country that relies upon imports for most of its supplies of feed protein supplements ranges from US$ 300 to US$ 400, depending upon its protein content. To this must be added: The cost to the farmer, then, ranges from US$ 320 for a ton of 27 percent protein feed for tilapia and carp to US$ 425 for one that contains 40 percent protein for trout. At these prices, the farmer breaks even if tilapia and carp fetch US$ 1.60/kg and trout US$ 2.13, at the farm gate 1/. Current prices for these fishes, especially for trout, in most countries are considerably higher, indicating the feasibility of employing ind… See full list on fao.org

China Food Machine manufacturer, Food Extruder, Textured Soy

China Food Machine supplier, Food Extruder, Textured Soy Protein Machine Manufacturers/ Suppliers – Jinan Saibainuo Machinery Co., Ltd.

Extruder | machine | Britannica

Other articles where Extruder is discussed: rubber: Shaping: Extruders are used to produce long continuous products such as tubing, tire treads, and wire coverings. They are also used to produce various profiles that can later be cut to length. Multiroll calenders are used to make wide sheeting. In transfer and injection molds, the

China Fish Food Machine, China Fish Food Machine

manual pet pellet feed processing machine/household birds fish turtles pellet food extruder machine This machine is for making pet food, like fish,birds and so on. Parameter of the machine: machine weight:1.2kg raw material:corn powder,bean powder. Machine pic FYR: Contact info:

Extrusion Technology in Food Processing – SlideShare

Feb 22, 2018 · Extruder Parts & Components Extrusion Drive: The Power supply in food extruder is done by Electric motors. The size of the motor depends on the capacity of the extruder and may be as large as 300 KW. The screw speed on extruder is a valuable control parameter. The speed on food extruders is normally less than 500 rpm. Thrust bearing must be

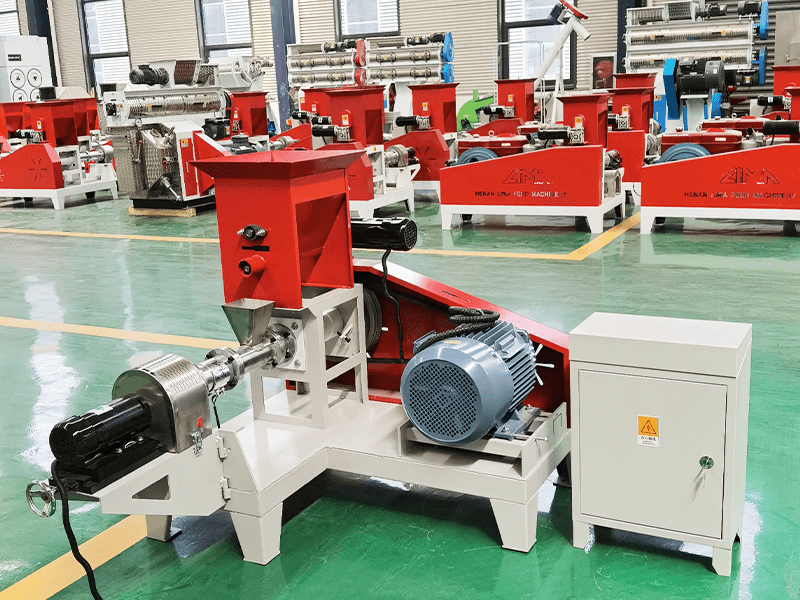

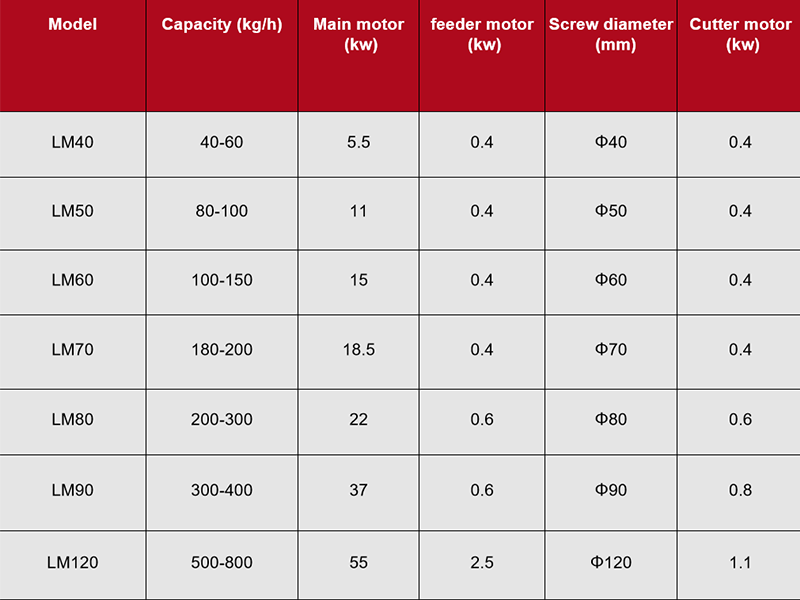

Fish Feed Machines and Floating Feed Production Line Manufacturer

Single screw fish feed processing line can be divided into 2 types: Small Dry Type Plant and Large Wet Type Plant, in accordance with what extruder you choose. WET TYPE: Super automation control and high production efficiency, it is the best choice for medium and big sized feed mills and breeding farms.

Mixing technology to handle ‘soup’ – All About Feed

Feb 20, 2019 · The best-known commercial solution until today is to not dry but to add up to 30% of this ‘soup’ of wet materials to other raw materials included in the fish feed directly in the extruder. Adding more than 30% is not recommended, as this would influence the viscosity of the feed matrix and thus decrease the cooking effect.

Fish feed production | Clextral

To date, Clextral and its industrial integration partners have installed over 100 fish feed manufacturing plants around the world including machines producing over 34 tons of pellets per hour. Clextral also works closely with research institutes in several countries to develop technology and recipes for aquaculture.

New technology of fish feed industries in Bangladesh

Perhaps this question doesn’t make any sense to many farmers or fishers or aquaculturists but our prime (মুখ্য) purpose is to disseminate (ছড়িয়ে দেয়া) fisheries knowledge everywhere and to connect with each relevant person who are somehow associated with fisheries activity e.g. fish culture.

Jinan Shengrun Machinery Co., Ltd. – Fish Feed Machine, Puff

Jinan Shengrun Machinery Co., Ltd., Experts in Manufacturing and Exporting Fish Feed Machine, Puff Snacks Machine and 1958 more Products. A Verified CN Gold Supplier on Alibaba.com.

How New Technology Is Making Plant-Based Foods Taste And Look

May 13, 2021 · The taste, texture, and appearance of many plant-based foods need improvement to gain greater acceptance from consumers. Now, Motif FoodWorks, a food technology company, announced it has gained

Fish feed – SlideShare

Aug 12, 2011 · Fish feed 1. Powerpoint Templates FISH FEED MANUFACTURING PLANT Presented by: Suan Scientific Instruments and Equipments Kolkata www.suanscientific.com Email : suanscientific_call@yahoo.co.in / saikatray159@gmail.com 2.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)