DRY BENEFICIATION OF BAUXITE MINERALS USING A

The ST Equipment & Technology (STET) tribo-electrostatic belt separator offers a novel beneficiation route to pre-concentrate bauxite ores. The STET dry separation process offers bauxite producers or bauxite refiners an opportunity to perform pre-Bayer-process upgrading of bauxite ore to improve the quality.

(PDF) Amino Acid Digestibility of Chemically Treated and

Feed and water was provided ad-libitum for a period of ten days as an adjustment period. Following 24 hours of fasting, each bird was given 25g of fine ground samples of untreated and differently treated DRP using crop intubation with a funnel

How pet food is made – making, used, processing, parts,

Ingredients vary somewhat depending on the type of pet food. The basic difference between canned and dry pet foods is the amount of moisture. Canned food contains between 70 and 80% moisture, since these are generally made from fresh meat products, while dry pet food contains no more than 10%.

ASME

ABOUT ASME ASME Mission To serve our diverse global communities by advancing, disseminating, and applying engineering knowledge for improving the quality of life and communicating the excitement of engineering. ASME Vision ASME, the American Society

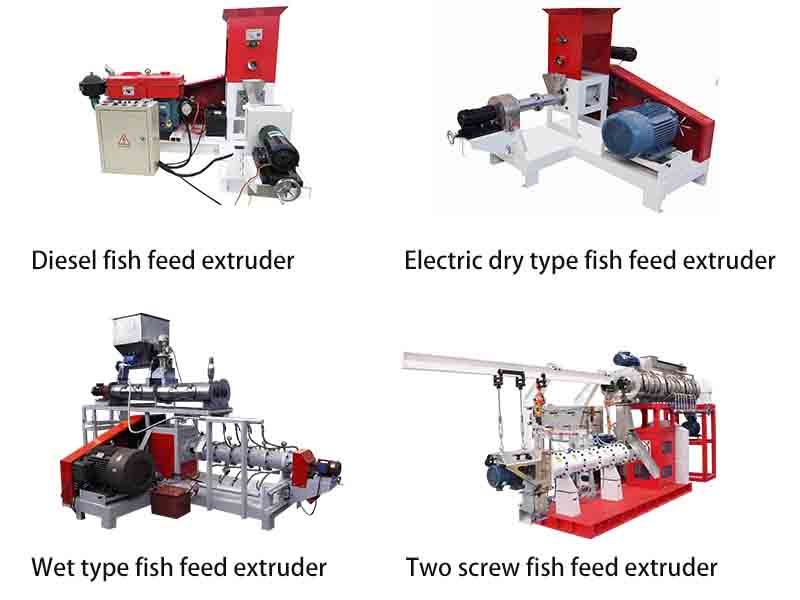

(PDF) Design of single screw extruder for homogenizing

The relationship between the linear displacement and the time of operation obeys the power law. Consequently, a 5 hp electric motor was selected to power the single crew extruder.

US4784860A – Pet food – Google Patents

A pet food containing a proteinaceous vegetable source component treated with an SPS-ase preparation in aqueous medium. Presence of this component imparts a decisive improvement in regard to the elasticity and palatability of the pet food. US4784860A US06/921,414 US92141486A US4784860A US 4784860 A US4784860 A US 4784860A US 92141486 A

Ernesto Aguilar | Universidad Autónoma de Sinaloa –

values of SME were obtained at high levels of FM throughout the range of BT and SFC, whereas the highest values of ΔE were obtained at high SFC and low FM. Increasing levels of SFC increased ΔE values, whereas EI and SME values decreased. The best

(PDF) Effect of Process Variables on Some System

Feed moisture and feed composition strongly influenced the SME, as expected decreasing feed moisture resulted in increased SME. Choudhury and Gautan (2003) reported that increasing the amount of fish solids in the hydrolyzated fish muscle and rice blend resulted in lowering the SME input, reducing mixing and increasing the mean residence time.

Effect of meal mixes properties on extrusion process and pellet

The response of the extruder was characterized by the specific mechanical energy (SME), specific thermal energy (STE) and screw back pressure (SBP). The pellet quality was defined as the radial expansion index, bulk density, retention, oil

Thermomechanical Cooking and Expansion Part 2 – Clextral

SME increase (screw speed) SME = 125 Wh/kg 3 SME = 132 Wh/kg SME = 145 Wh/kg SME = 152 Wh/kg The higher the SME, the finer the cell structure 20

Extruded Aquaculture Feed: A Review | IntechOpen

20/12/2017 · The feed conversion ratio shows the inverse relationship between feed intake and weight gain of the fish and is related to the digestibility and metabolic use of the diet []. Trout fed with fishmeal or 15 and 30% of bean flour also had the same ( p > 0.05) specific growth rate (SGR), but not trout fed with 45% of bean flour in their diets.

(PDF) Effect of screw configuration and raw material on

Download Free PDF Effect of screw configuration and raw material on some properties of barley extrudates Journal of Food Engineering, 2009 Medeni Maskan Aylin Altan Kathryn McCarthy Medeni Maskan

(PDF) Developement of extruded flakes from pearl millet –

PDF | Pearl millet being a good source protein, fiber and mineral can prove to be a great source of product addition to healthy and balanced diet, but | Find, read and cite all the research you …

A Comparative Study on Torque Requirement During

5/3/2011 · Extrusion pretreatment of biomass can be one of the viable continuous pretreatment methods. The torque requirement of feedstock during extrusion was an important factor, and it was not reported in the literature. Screw compression ratio, screw speed, barrel temperature, and feedstock moisture content are the contributing factors to the torque. The current study was

(PDF) Optimization of extrusion conditions for …

The aim of this work is to study the extrusion process and optimum conditionsfor development of maize-fish based extruded snacks by using Design-Expert® software for Response Surface Methodology (RSM). However, there are still low developed