Causes and treatment methods of blockage caused by wood

Causes and treatment methods of blockage caused by wood pellet machine Sawdust pellet machines often encounter blockages during use, which is a headache for many customers. Let’s look at its working principle first, and then analyze the cause and treatment of the blockage.

US20080290548A1 – Pellet mill die and pelletizing process

An improved pellet mill is shown which has an annular die of the kind having a multiplicity of radial bores through which raw material is extruded to form pellets. The annular body of the die has an inner circumferential surface which defines a compression side of the die, and an outer circumferential surface which defines a discharge side of the die.

(PDF) Design and production of a fish feed pelletizing machine

the pellet has been used by various industries to describe a variety of The shaft also extends out of the die plate … which is suitable for fish and poultry farming. The machine was produced …

China Spare Parts for Pellet Machine/Gear Wheel/Shaft

Spare Parts for Pellet Machine/Gear Wheel/Shaft/Roller Assembly/Bearing Introduction of Ring die Ring die is an very important part of ring die pellet machine in the whole manufacturing process. The quality of ring die not only directly relates with the quality and output of pellets, but also the running state of equipment and maintenance cost.

Wholesale Poultry Feed Animal Fodder Poultry Feed Pellet

Feed Pellet Making Machine, Animal Feed Pellet Machine, Animal Feed Making Machine manufacturer / supplier in China, offering Wholesale Poultry Feed Animal Fodder Poultry Feed Pellet Making Machine, Industrial Pineapple Lichee Orange Juicing Making Machine, Vegetables Fruit Juice Extractor for Sale, Mobile Timber Wood Cutting Band Saw Machine, Horizontal Wood Sawing Band Sawmill and so on.

The Pelleting Process – CPM

Die speed (RPM) is a function of the feeds to be pelleted, for example, feeds containing fat or 50-60% corn. Perhaps it is more judicious to refer to peripheral speed of a die rather than RPM. An exaggerated example is producing a 3/4” cube at 317 RPM with a 22” die vs. 171 RPM with the same die.

FEED AND BIOFUEL SPARE AND WEAR PARTS – ANDRITZ

The Flat die series is compatible with various brands of vertical pellet mills. The configuration of the die and the base ma-terials used are determined by the application and the abrasiveness of the substances being pelletized. NO.: 4.3A ROLL SHELLS Roller shells utilized in the process of pressing milling ingredients through the die.

pellet mill main shaft – Alibaba

forging main shaft for 420 feed/wood pellet mill Product description: Roller shaft is one of important parts in roller assembly of pellet mill machine, the role of r oller shaft is to adjust the gap between the ring die and roller.

Chapter 18. Feed Milling Processes

As the die rotates, feed is pressed against its inner wall by a set of 3 rollers (9). Due to its high rotational speed and heavy load, the die has to be securely harnessed to the shaft. This is achieved by means of a two-piece die cover assembly (10) and 12 strong bolts (11).

Assembly and Details machine drawing pdf

5]assembly of screw jack 11. 5] details of screw jack 12. 6] cross head assembly 13. 6] details of cross head 14. 7] assembly of revolving centre 15. 7] details of revolving centre 16. 8] assembly of milling machine tail-stock 17. 8] details of milling machine tail-stock 18. 9] assembly of crane hook 19.

Main Motor and Rotor Assembly for MUZL 610TW Type Pellet Mill

Sep 22, 2013 · Main motor This type of pelleting machine includes two main motors, which are symmetrically installed at both sides of the pellet mill. The two motors shall rotate in the same direction and finally the ring die shall rotate in clockwise. The two motors shall startup in star form at the same time, while under normal operation speed the one is transmitted to a triangle connection firstly, and

Pellet Machine & Worm Shaft Manufacturer from Sangli

Manufacturer of Pellet Machine, Worm Shaft, Iron Rod, Paddle Conveyor and Gear Part offered by Samadhan Engineering Works, Sangli, Maharashtra.

Drive shaft – Wikipedia

A drive shaft, driveshaft, driving shaft, tailshaft (Australian English), propeller shaft (prop shaft), or Cardan shaft (after Girolamo Cardano) is a vehicle component for transmitting mechanical power and torque and rotation, usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to allow for relative movement between them.

Machinio – Used construction equipment, agricultural

CNC Machine Tools, New Showroom Gap Frame & Straight-Side Presses, Metalworking and Support Equipment from the Service & Repair Division Featured Huge Live In-Person Auction – Hundreds of Farm and Construction Pieces.

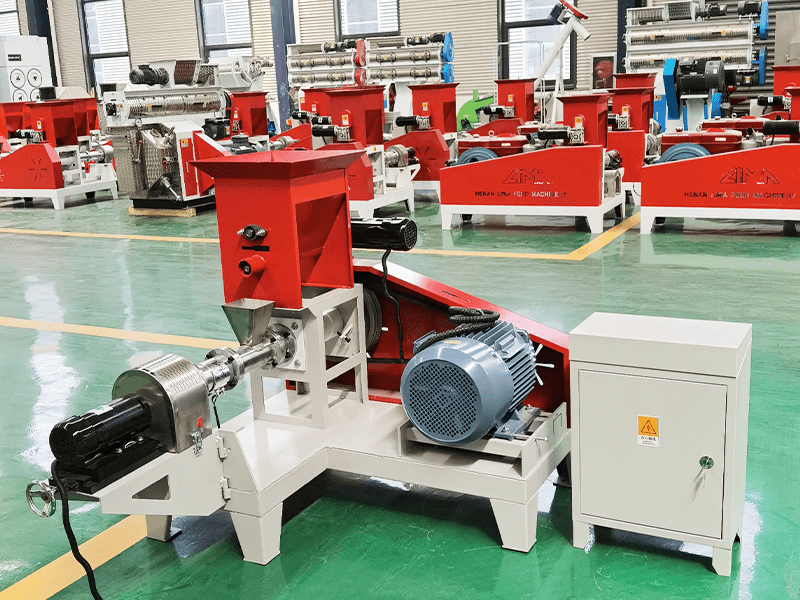

October 2017 – floating fish feed pellet mill/animal feed

As we all know, the floating fish feed extruder can be divided into two types. One is dry type without conditioner, the other is wet type with conditioner. Comparing with dry type fish feed machine. the capacity of the wet type is higher.The wet type pellet extruder should be equipped with a boiler for providing steam to its container.The machine is widely used for producing grains into high

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)