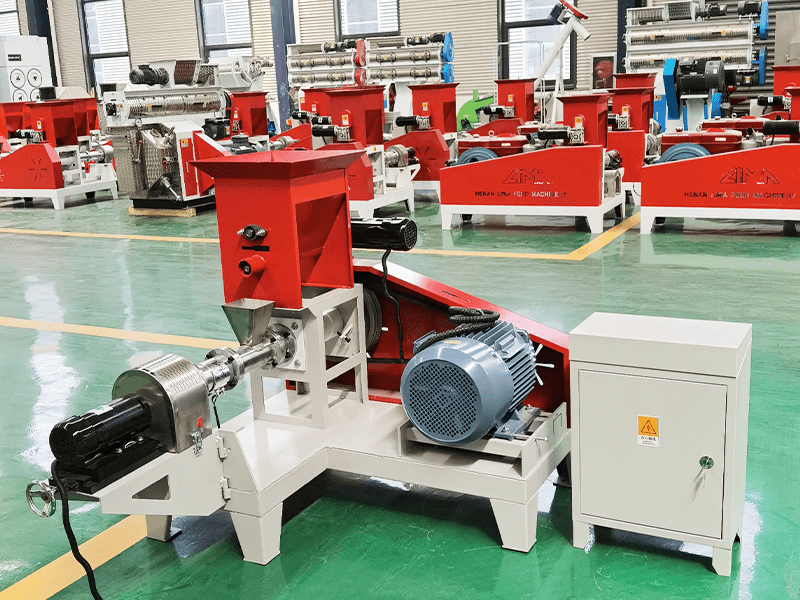

China 40-4000kg/H Floating Fish Feed Extruder Manufacturer

animal floating fishfeed dog pet food pellet making processing extruder machine Product Description. DGP Single Screw Pet Food Making Extruder Machine For Animal Feed Extruder is widely used for producing grains into high-grade aquatic feed pellets for fish,catfish,tilapia,shrimps,crab etc.The produced fish feed pellets can float on the water surface without dissolution for over 12 hours

Perfect quality floating fish feed pellet making machine

Perfect quality floating fish feed pellet making machine SEARCH Massalfa Microwave – Whether it’s agriculture or construction equipment your working on, Has theFish Feed/Pet Food/treats process line Not Rated precision rating: you 320000 N dynamic load capacity: need.

Extrusion Cooking Technology for Foods: A Review

Extrusion-cooking is increasing popularity in the global agro-food processing industry, particularly in the food and feed sectors. Extrusion cooking is a high-temperature, short-time process in which moistened, expansive, starchy and protenacious raw material is used. Food materials

Dsp80 Floating Fish Feed Making Machine Wet Type Shrimp

Dsp80 Floating Fish Feed Making Machine Wet Type Shrimp Feed Extruder , Find Complete Details about Dsp80 Floating Fish Feed Making Machine Wet Type Shrimp Feed Extruder,Fish Feed Making Machine,Floating Fish Feed Machine,Feed Pellet Machine from Feed Processing Machines Supplier or Manufacturer-Henan Hanson Industry Co., Ltd.

Versatile twin screw extruder ideal for aquafeed – All

The aquafeed manufacturing industry is widely recognised as one of the fastest expanding agricultural industries in the world. Fish meal is the main protein source in aquafeed, but supply is limited, which means that alternative sources need to be used. From a processing point of view extrusion is the most efficient way of turning plant protein into fish feed. Twin screw extruders have a

Fish feed plants for the industry | AMANDUS KAHL

Our KAHL fish feed plants are equipped with the latest process technology, the core of which is the extrusion system with the extruder OEE 25 NG and the process control system ESEP. Process sequence. A fish feed plants includes several individual machines for conveying, proportioning, pre-treatment and subsequent cooling and storage.

Difference Between Feed Extruder And Feed Pellet Machine

Extrusion is a high temperature short time (HTST) heating process, it minimizes the degradation of food nutrients while improving the digestibility of protein and starches. Fish feed extruder is an ideal machine that designed for processing floating or sinking aquaticfeed just by adjusting the formula.

Factors Affecting Fish Feed Water Stability and Feed

The water stability of fish feed pellet refers to the performance of keeping constituent from dissolution and diffusion after fish feed soaking in water for a certain period time. In general, stability is indicated with the ratio of fish feed diffusion amount and quality in water per unit time, or with the minimum time without diffusion for fish feed in water, which always requires the

Fish Feed Extruder – Food Machinery Direct Sales Manufacturers

The extrusion equipment for fish feed production can adjust the process parameters such as raw material, temperature and moisture, so that the fish feed has the characteristics of long floating time, hard to disperse, novel shape, unique taste, rich nutrition and delicate organization, which is suitable for different fish tastes.

Fish Feed Pellet Dyer -Electric and Gas Type for Choice

Fish Feed Extruder Spare Parts; Fish Feed Hammer Mill; heating temperature, materials staying time and feeding speed can be adjusted to achieve the best drying effect. 3. Simple structure, easy installation and maintenance. 4. Mostly used in requirement of low drying speed and long drying time. 5. Ideal for drying feed pellets, grains,etc …

Floating Fish Feed Pelletizer for Tilapia,Koi,Catfish etc

Start with dry type fish feed extruder,pellets diameter is 0.9-15mm and floating time is >12hrs. Electric heating device is adopted to improve the feed expansion rate and pellets floating time. 4. Auto-temperature control system makes the temperature controlling more direct viewing and

Aquafeed Twin Screw Extrusion Processing

preparation (grinding in particular), extrusion processing, drying, fat coating and cooling are discussed. Special emphasis is presented on those unit operations which affect the quality of aquafeed pellets. These include pre-conditioning of feed mixes (heat balance, hydration time, and residence time distribution), thermo-mechanical cooking in

FEED AND BIOFUEL ADVANCED FEED PRODUCTION

3 The advanced single-screw and twin-screw extrusion concept FEATURES Type EX0618 EX0621 EX1021 EX1250 EXTS718 Transmission belt belt belt gear gear third party Bolt barrels – – – x x Screws pinned pinned pinned pinned spline Water cooling or heating jackets x x x x x Liquid injection points x x x x x Screw pushout – – – – x Dual and single conditioner x x x x x

Fish Feed Extruder, 20-25 kg per hr, Rs 135000 /piece

Proveg Engineering & Food Processing Private Limited – Offering Fish Feed Extruder, 20-25 kg per hr at Rs 135000/piece in Pune, Maharashtra. Read about company. Get contact details and address |

Steam heating Twin screw extruder machine for fish feed

2)Corn, soybean etc should be crushed before coming into extruder machine, the finer the raw materaisl is, the more easier raw materaiwl will be cooked in the barrel of the extruder machine. But for fish and aquatic, it is very difficult for them to digest pelelts with big diameter, so the finer the raw materails , the effect will be better

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)